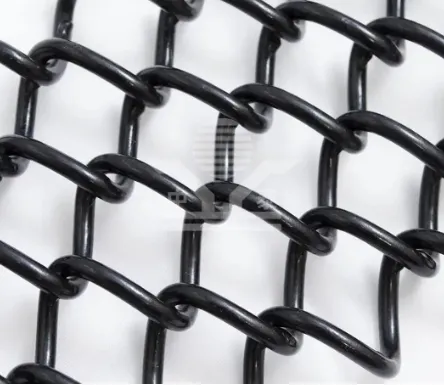

Metal Safety Grating Ensuring Safety and Versatility

Metal safety grating is an essential component in various industrial and commercial applications, providing a reliable solution for safety and functionality. Typically constructed from steel, aluminum, or fiberglass, metal grating offers numerous benefits that make it a popular choice across different sectors, including construction, manufacturing, and transportation.

One of the primary advantages of metal safety grating is its ability to provide a safe walking surface. The open design of grates allows for the easy passage of water, debris, and other materials, reducing the risks of slip-and-fall accidents. This is particularly important in environments where liquids or chemicals may be present, as the grating can prevent the buildup of hazardous substances on walkways, ensuring a safer working environment for employees and visitors alike.

Moreover, metal grating is highly durable and resistant to various environmental factors. Most metal gratings are designed to withstand heavy loads, making them ideal for use in areas with high foot traffic or where heavy equipment is used. For instance, in manufacturing plants, metal grates can support forklifts and other machinery without compromising structural integrity. Their resilience also makes them suitable for outdoor use, as they can endure extreme weather conditions, including rain, snow, and UV exposure.

metal safety grating

In addition to safety and durability, metal safety grating is known for its versatility

. Grating systems can be tailored to fit specific applications by varying their materials, sizes, and load capacities. This adaptability makes it easy to integrate metal grating into different settings, from pedestrian walkways and loading docks to industrial floors and wastewater treatment facilities. Furthermore, various surface treatments, such as coatings and finishes, can enhance the grating's corrosion resistance and aesthetic appeal.Another essential factor to consider is the ease of installation and maintenance. Metal grating panels can be prefabricated and quickly installed, significantly reducing labor costs and downtime. Once in place, these grates require minimal maintenance, as their durable materials resist wear and tear over time. Regular inspections and cleanliness checks are typically sufficient to keep metal safety grating in optimal condition, further contributing to its appeal in industrial settings.

Lastly, as industries increasingly prioritize safety, compliance with regulations and standards is paramount. Metal safety grating is designed to meet or exceed many safety codes and standards, giving businesses peace of mind that they are adhering to legal and operational requirements. This adherence not only protects employees and clients but also enhances a company’s reputation as a responsible and safety-conscious organization.

In conclusion, metal safety grating is a critical component in enhancing safety and functionality across various applications. Its durability, versatility, ease of installation, and compliance with safety standards make it an invaluable asset for businesses seeking to create safer work environments. As industries continue to evolve, the demand for reliable safety solutions like metal grating will undoubtedly rise, ensuring that safety remains a top priority in every workspace. Investing in high-quality metal safety grating can lead to significant improvements in operational efficiency, employee satisfaction, and overall safety.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.