1 月 . 25, 2025 02:32

Back to list

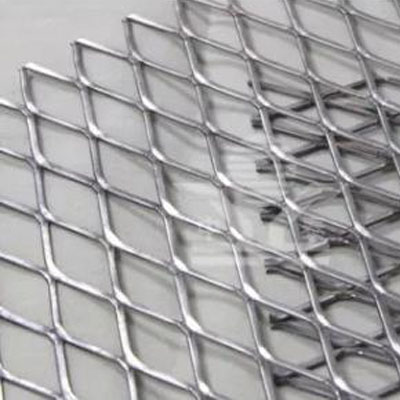

metal safety grating

Understanding the Importance of Metal Safety Grating

Establishing trustworthiness in metal safety grating involves looking at its track record in various industries. Over the years, numerous studies and field trials have validated its effectiveness in enhancing workplace safety. Industry reports consistently highlight the reduction in workplace accidents post-installation of metal gratings, emphasizing their importance as a preventative safety measure. This empirical evidence supports the trust that facilities place in metal safety gratings. Selecting the right grating involves understanding the specific needs of your industry and application. Factors such as the environmental conditions, load requirements, and the presence of substances that could affect the grating's performance must be considered. For instance, in marine environments, gratings with high resistance to rust and salt corrosion are essential, thereby ensuring longevity and minimizing maintenance costs. Once installed, proper maintenance of metal safety grating is crucial. While these gratings are designed to withstand harsh conditions, routine inspections and cleaning can greatly extend their lifespan. For instance, regularly removing debris from the surface can prevent slipping hazards and maintain the grating's non-slip properties. In addition, checking for signs of wear and tear can help anticipate necessary replacements before safety is compromised. Reflecting on the strategic use of metal safety grating, it is clear that its role transcends basic safety measures. It supports operational efficiency by providing a stable environment for workers, thus minimizing downtime caused by accidents. Consequently, investing in high-quality metal safety grating is both a financial and ethical decision, proving to be indispensable across industries like manufacturing, oil and gas, and construction. In conclusion, metal safety grating stands as a testament to the advancement of safety solutions in industrial settings. Its proven track record, coupled with compliance to international safety standards, reinforces its position as a critical component of workplace safety infrastructure. As industries continue to evolve, the demand for reliable safety measures like metal safety grating will undoubtedly remain at the forefront.

Establishing trustworthiness in metal safety grating involves looking at its track record in various industries. Over the years, numerous studies and field trials have validated its effectiveness in enhancing workplace safety. Industry reports consistently highlight the reduction in workplace accidents post-installation of metal gratings, emphasizing their importance as a preventative safety measure. This empirical evidence supports the trust that facilities place in metal safety gratings. Selecting the right grating involves understanding the specific needs of your industry and application. Factors such as the environmental conditions, load requirements, and the presence of substances that could affect the grating's performance must be considered. For instance, in marine environments, gratings with high resistance to rust and salt corrosion are essential, thereby ensuring longevity and minimizing maintenance costs. Once installed, proper maintenance of metal safety grating is crucial. While these gratings are designed to withstand harsh conditions, routine inspections and cleaning can greatly extend their lifespan. For instance, regularly removing debris from the surface can prevent slipping hazards and maintain the grating's non-slip properties. In addition, checking for signs of wear and tear can help anticipate necessary replacements before safety is compromised. Reflecting on the strategic use of metal safety grating, it is clear that its role transcends basic safety measures. It supports operational efficiency by providing a stable environment for workers, thus minimizing downtime caused by accidents. Consequently, investing in high-quality metal safety grating is both a financial and ethical decision, proving to be indispensable across industries like manufacturing, oil and gas, and construction. In conclusion, metal safety grating stands as a testament to the advancement of safety solutions in industrial settings. Its proven track record, coupled with compliance to international safety standards, reinforces its position as a critical component of workplace safety infrastructure. As industries continue to evolve, the demand for reliable safety measures like metal safety grating will undoubtedly remain at the forefront.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP