Light Duty Grating An Overview

Light duty gratings are integral components used in various applications across different industries, primarily for their ability to support and distribute loads while allowing for the passage of light and air. These gratings are characterized by their lightweight design, making them an ideal choice for projects that require both strength and flexibility. This article delves into the features, materials, applications, and benefits of light duty gratings.

What Are Light Duty Gratings?

Light duty gratings are typically made from materials that provide a good balance between structural integrity and ease of handling. Common materials used include fiberglass, aluminum, and steel, each chosen based on the specific requirements of the application. The design of these gratings includes an array of parallel bars or slats, which are spaced to allow light and air to pass through while supporting foot traffic or equipment loads.

The defining features of light duty gratings include their load-bearing capacity, resistance to corrosion, and lightweight structure. They are usually rated for maximum load capacities ranging from 200 to 500 pounds, depending on the manufacturer's specifications and the material used.

Common Materials

1. Fiberglass Reinforced Plastic (FRP) This is one of the most popular materials for light duty gratings due to its durability and resistance to chemicals and corrosion. FRP gratings are lightweight, non-conductive, and require minimal maintenance, making them ideal for industrial environments.

2. Aluminum Aluminum gratings are known for their lightweight properties and excellent corrosion resistance. They are often used in industries where weight savings are crucial, and their anodized finish provides enhanced durability.

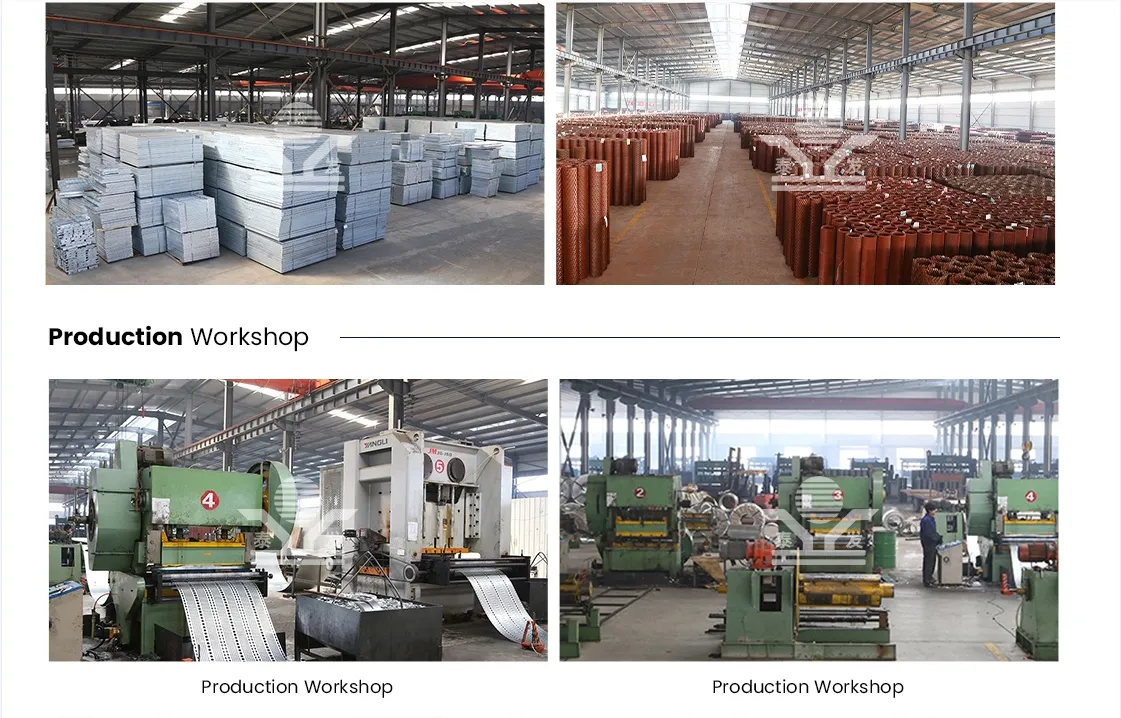

3. Steel While steel gratings are generally heavier than their fiberglass and aluminum counterparts, they offer great strength and load-bearing capacities. Steel light duty gratings are often hot-dipped galvanized to provide an additional layer of protection against rust and corrosion.

Applications of Light Duty Gratings

Light duty gratings are widely used across various sectors

. Some of the most common applications includelight duty grating

- Walkways and Platforms Light duty gratings provide safe and stable walking surfaces in industrial settings, parks, and commercial buildings. - Drainage Covers They are often used as grates for gutters and drainage systems, allowing water to flow through while preventing larger debris from entering. - Filtration Systems Used in various industries for filtration applications, light duty gratings facilitate the efficient passage of air or liquids while maintaining structural integrity. - Stair treads and Landings Besides walkways, light duty gratings offer reliable solutions for staircases and landings, providing slip resistance and strength.

Benefits of Using Light Duty Gratings

The use of light duty gratings offers numerous benefits

1. Weight Savings Their lightweight nature simplifies installation and reduces labor costs, making them a cost-effective solution for many projects.

2. Versatility Light duty gratings can be customized to fit various shapes and sizes, making them adaptable to different architectural designs.

3. Safety With appropriate slip-resistant surfaces, light duty gratings improve safety in high-traffic areas, reducing the risk of accidents.

4. Low Maintenance Materials like fiberglass and aluminum require less upkeep than traditional materials like wood or concrete, leading to long-term cost savings.

5. Aesthetics Light duty gratings can be aesthetically pleasing, offering various finishes and colors that can enhance the overall look of a space.

Conclusion

Light duty gratings play a crucial role in modern infrastructure, providing effective solutions for load distribution and ventilation. Their versatility, coupled with the advancements in material technology, ensures that they remain a reliable choice for a myriad of applications. As industries continue to strive for efficiency and safety, the significance of light duty gratings will undoubtedly grow, making them a vital component in future engineering designs.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.