2 月 . 06, 2025 05:17

Back to list

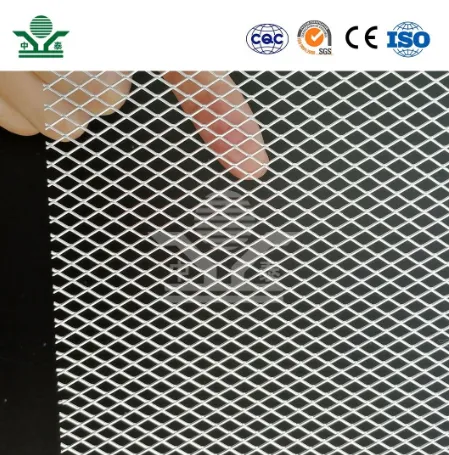

Zhongtai Stainless Steel 316 Crimped Wire Mesh China Manufacturing 3mm 0.3mm 1mm 1.5mm Aperture Crimped Knitted Wire Mesh

In the realm of architectural elegance and industrial efficiency, laser cut perforated metal panels have emerged as an unparalleled choice for designers and engineers alike. These panels, which stand at the intersection of art and function, are celebrated for their versatility, durability, and aesthetic appeal — characteristics that make them a cornerstone in both commercial and residential projects.

When speaking to their durability, it is crucial to note that perforated metal panels are constructed from materials such as steel, aluminum, and stainless steel, known for their longevity and resistance to weathering. This makes them especially attractive for exterior applications, where exposure to the elements is a concern. Maintenance is minimal due to their corrosion-resistant properties, meaning they retain their aesthetic appeal and structural integrity over extensive periods. Applications Across Industries The application of laser cut perforated metal panels spans an array of industries. In architecture, they are commonly seen on building facades, parking garages, and interior design projects. In the industrial sector, they function effectively as filtration and screening tools, while in automotive manufacturing, these panels are integral to the production of vehicle grilles and ventilation systems. Sustainable Design Principles Incorporating perforated metal panels into project designs aligns with sustainable design principles. Their recyclability and long life span mean less material waste and a reduced environmental footprint. As the world continues to focus on sustainability, the role of such materials in promoting eco-friendly building practices cannot be understated. Expert Guidance and Customization When opting for laser cut perforated panels, collaboration with experts in the field is advisable. Professionals in this industry offer detailed guidance on material selection, pattern design, and application suitability, ensuring that the final product meets both aesthetic and functional requirements. Customization is a significant advantage, with manufacturers providing bespoke solutions tailored to specific project needs. In summary, laser cut perforated metal panels are an embodiment of innovation and practicality. They enhance the structural and visual elements of spaces, provide a sustainable option for modern building challenges, and stand as a testament to the evolving nature of design and functionality. Adopting these panels into your project signifies not just a choice of material but a commitment to quality, efficiency, and environmental responsibility.

When speaking to their durability, it is crucial to note that perforated metal panels are constructed from materials such as steel, aluminum, and stainless steel, known for their longevity and resistance to weathering. This makes them especially attractive for exterior applications, where exposure to the elements is a concern. Maintenance is minimal due to their corrosion-resistant properties, meaning they retain their aesthetic appeal and structural integrity over extensive periods. Applications Across Industries The application of laser cut perforated metal panels spans an array of industries. In architecture, they are commonly seen on building facades, parking garages, and interior design projects. In the industrial sector, they function effectively as filtration and screening tools, while in automotive manufacturing, these panels are integral to the production of vehicle grilles and ventilation systems. Sustainable Design Principles Incorporating perforated metal panels into project designs aligns with sustainable design principles. Their recyclability and long life span mean less material waste and a reduced environmental footprint. As the world continues to focus on sustainability, the role of such materials in promoting eco-friendly building practices cannot be understated. Expert Guidance and Customization When opting for laser cut perforated panels, collaboration with experts in the field is advisable. Professionals in this industry offer detailed guidance on material selection, pattern design, and application suitability, ensuring that the final product meets both aesthetic and functional requirements. Customization is a significant advantage, with manufacturers providing bespoke solutions tailored to specific project needs. In summary, laser cut perforated metal panels are an embodiment of innovation and practicality. They enhance the structural and visual elements of spaces, provide a sustainable option for modern building challenges, and stand as a testament to the evolving nature of design and functionality. Adopting these panels into your project signifies not just a choice of material but a commitment to quality, efficiency, and environmental responsibility.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP