Understanding 3mm Perforated Aluminium Sheet Applications and Benefits

In the realm of materials used across various industries, perforated aluminium sheets have gained significant prominence due to their unique properties and versatile applications. Among the different specifications available, the 3mm perforated aluminium sheet stands out for its balance of strength and lightweight nature, making it ideal for a myriad of uses.

What is a Perforated Aluminium Sheet?

Perforated aluminium sheets are thin panels that have been punched with holes in a systematic pattern. The process of perforation not only allows for ventilation and sound absorption but also provides aesthetic benefits, giving the sheets an appealing design. The thickness of the sheet, in this case, 3mm, strikes a balance between durability and flexibility, making it suitable for both structural and decorative purposes.

Key Benefits of 3mm Perforated Aluminium Sheets

1. Lightweight yet Strong Aluminium is known for its lightweight properties, and a 3mm sheet retains that quality while providing sufficient strength for various applications. This combination minimizes the load on supporting structures while maintaining the required durability.

2. Corrosion Resistance One of the remarkable features of aluminium is its resistance to corrosion. This property extends the lifespan of the product, making 3mm perforated aluminium sheets especially suitable for outdoor use and environments prone to moisture.

3. Aesthetic Versatility The perforation patterns can be customized to meet specific design needs. This aesthetic feature allows architects and designers to incorporate these sheets into building facades, interiors, and artistic installations, enhancing the visual appeal of structures.

4. Ventilation and Light Transmission The holes in the perforated sheets not only serve decorative purposes but also facilitate air flow and light penetration. This makes them ideal for applications where ventilation is crucial, such as in acoustic panels for sound management or in façade systems that require natural light without compromising privacy.

3mm perforated aluminium sheet

5. Recyclability Aluminium is a highly recyclable material. Using 3mm perforated aluminium sheets contributes to sustainable building practices, as these sheets can be recycled at the end of their lifecycle, reducing waste and environmental impact.

Applications of 3mm Perforated Aluminium Sheets

1. Architectural Design Architects often use perforated aluminium sheets for cladding and façade systems, adding an element of modernity to buildings while also allowing for natural ventilation.

2. Industrial Uses In various industrial settings, 3mm perforated sheets are employed in machinery guards, separation screens, and filtration systems due to their durability and strength.

3. Commercial Applications Retail spaces utilize these sheets in displays, decorative panels, and for creating acoustic environments to enhance the shopping experience.

4. Transportation The lightweight nature of aluminium makes it a favorable choice in the transportation sector. Applications include partitioning in trains, buses, and airplanes, where weight restrictions are paramount.

5. Furniture Design Designers increasingly incorporate 3mm perforated aluminium sheets into furniture pieces, creating unique table designs, partitions, or shelving units that blend strength with style.

Conclusion

The 3mm perforated aluminium sheet serves as a prime example of a material that meets various functional and aesthetic needs. Its lightweight nature, strength, and versatility make it invaluable across numerous industries, from construction and architecture to transportation and furniture design. As sustainability becomes a crucial consideration in material selection, the recyclability of aluminium further enhances its appeal. For anyone involved in design, architecture, or manufacturing, understanding the benefits and applications of 3mm perforated aluminium sheets is essential in making informed decisions that combine functionality with aesthetic appeal.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

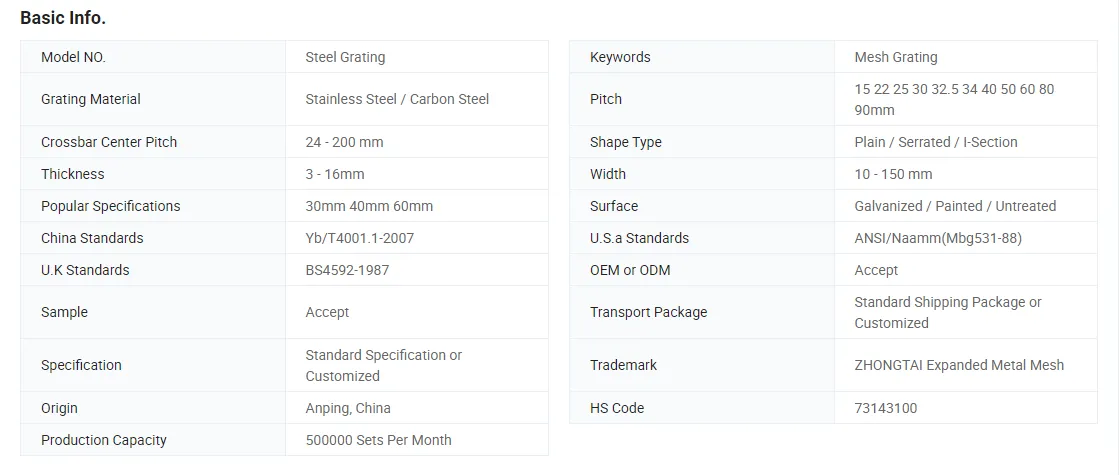

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.