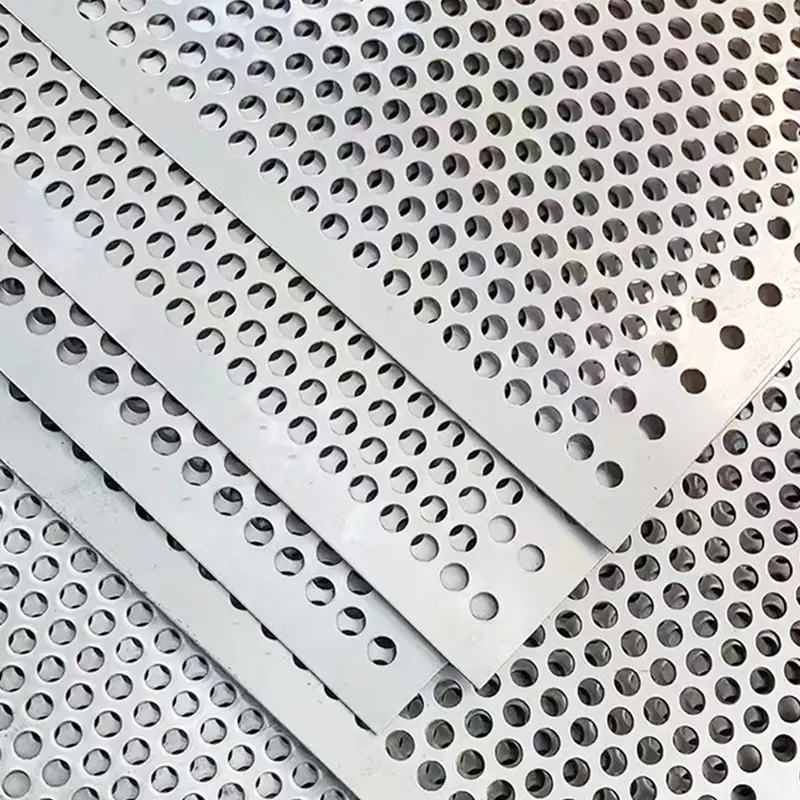

The Versatility of Hexagonal Perforated Aluminum Sheets

Hexagonal perforated aluminum sheets are increasingly gaining popularity across various industries due to their unique properties and versatile applications. Characterized by their distinctive hexagonal patterns, these sheets are not only functional but also aesthetically pleasing, making them a favored choice for architects and designers.

One of the primary benefits of hexagonal perforated aluminum sheets is their lightweight nature. Aluminum, as a material, is known for its excellent strength-to-weight ratio. When perforated in a hexagonal pattern, the sheets maintain structural integrity while significantly reducing weight. This characteristic is particularly advantageous in industries such as construction, transportation, and manufacturing, where component weight can impact overall performance and efficiency.

In addition to their weight advantages, hexagonal perforated aluminum sheets offer superior durability. Aluminum is naturally resistant to corrosion, ensuring that these sheets can withstand exposure to harsh environmental conditions. When used in outdoor applications, such as architectural facades or outdoor furniture, this corrosion resistance extends the lifespan of the material, making it a cost-effective choice in the long run.

The design flexibility offered by hexagonal perforated aluminum sheets is also noteworthy. The hexagonal pattern not only provides a distinct visual appeal but can also be tailored to meet specific needs. The size and spacing of the holes can be customized according to the application, allowing designers to achieve desired levels of light and airflow while maintaining privacy. This adaptability makes them suitable for a wide range of uses, from interior design elements to exterior cladding.

hexagonal perforated aluminum sheet

Moreover, these sheets contribute to energy efficiency in building designs. The perforations in the sheets allow for natural ventilation, helping to regulate indoor temperatures and reduce reliance on mechanical heating and cooling systems. This feature is particularly valuable in the context of sustainable architecture, where the emphasis is on creating energy-efficient buildings that minimize environmental impact.

In addition to architectural applications, hexagonal perforated aluminum sheets find their place in various industries, including automotive, aerospace, and electronics. In the automotive sector, they are used for grille designs, providing both functionality and style. In aerospace, their lightweight property is essential for components that require high strength without adding excessive weight. Additionally, in electronic devices, they serve as heat sinks, allowing for effective thermal management.

Furthermore, the ease with which hexagonal perforated aluminum sheets can be fabricated adds to their appeal. They can be easily cut, shaped, and processed to meet specific project requirements, making them a practical choice for manufacturers and fabricators. The ability to quickly adapt the material for diverse purposes ensures that it remains relevant in an ever-evolving industrial landscape.

In conclusion, hexagonal perforated aluminum sheets exemplify the ideal blend of functionality and style. Their lightweight nature, durability, design flexibility, and energy efficiency make them a versatile solution across multiple industries. As innovation continues to drive material science forward, it is likely that we will see even more creative applications for these unique sheets in the future. Whether in architecture, automotive, or electronics, the enduring appeal of hexagonal perforated aluminum sheets is a testament to their value in today's marketplace.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.