1 月 . 22, 2025 04:53

Back to list

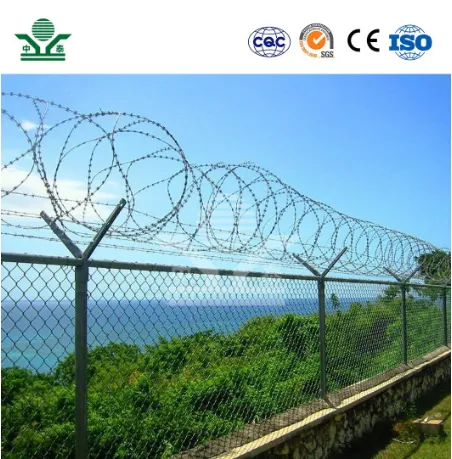

Australia Temporary Fence

Heavy duty floor grating has emerged as an essential solution for both industrial and commercial environments, offering unparalleled durability, safety, and versatility. Engineered to withstand heavy loads and resist environmental damages, these gratings play a crucial role in maintaining efficient and safe operations. Understanding the nuances of heavy duty floor grating is crucial for businesses seeking long-lasting infrastructure solutions.

Installation and maintenance are key considerations in optimizing the value of heavy duty floor grating. Proper installation by experienced professionals ensures that the grating performs to its fullest potential. Maintenance, though minimal, generally involves regular inspections to check for any signs of wear or damage, particularly in high-traffic areas. Cleaning the grating to remove debris or substances that could impede its open design function is also essential, preserving its safety and efficacy over time. As industry standards evolve, heavy duty floor grating continues to adapt, incorporating advanced materials and innovative designs to address emerging needs. The integration of technology in manufacturing processes has resulted in gratings that boast enhanced performance characteristics, such as improved load distribution and resistance to more aggressive industrial conditions. This evolution ensures that businesses can rely on grating solutions that not only meet current demands but are also future-proof. Experts within the field underline the importance of consulting with manufacturers and industry specialists when choosing heavy duty floor grating. This collaboration ensures that all unique requirements and potential challenges are addressed, leading to a solution that aligns perfectly with operational needs. Such engagement not only fortifies the grating's functional aspects but also supports the broader goals of operational safety, cost management, and environmental responsibility. In summary, heavy duty floor grating stands out as a product that seamlessly blends performance with practicality. By investing in high-quality, tailored grating solutions, businesses not only enhance their infrastructural integrity but also position themselves as leaders in safety and sustainability within their respective industries. The strategic selection and maintenance of heavy duty floor grating ultimately translate into tangible benefits, reinforcing its status as an invaluable asset in modern industrial and commercial settings.

Installation and maintenance are key considerations in optimizing the value of heavy duty floor grating. Proper installation by experienced professionals ensures that the grating performs to its fullest potential. Maintenance, though minimal, generally involves regular inspections to check for any signs of wear or damage, particularly in high-traffic areas. Cleaning the grating to remove debris or substances that could impede its open design function is also essential, preserving its safety and efficacy over time. As industry standards evolve, heavy duty floor grating continues to adapt, incorporating advanced materials and innovative designs to address emerging needs. The integration of technology in manufacturing processes has resulted in gratings that boast enhanced performance characteristics, such as improved load distribution and resistance to more aggressive industrial conditions. This evolution ensures that businesses can rely on grating solutions that not only meet current demands but are also future-proof. Experts within the field underline the importance of consulting with manufacturers and industry specialists when choosing heavy duty floor grating. This collaboration ensures that all unique requirements and potential challenges are addressed, leading to a solution that aligns perfectly with operational needs. Such engagement not only fortifies the grating's functional aspects but also supports the broader goals of operational safety, cost management, and environmental responsibility. In summary, heavy duty floor grating stands out as a product that seamlessly blends performance with practicality. By investing in high-quality, tailored grating solutions, businesses not only enhance their infrastructural integrity but also position themselves as leaders in safety and sustainability within their respective industries. The strategic selection and maintenance of heavy duty floor grating ultimately translate into tangible benefits, reinforcing its status as an invaluable asset in modern industrial and commercial settings.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP