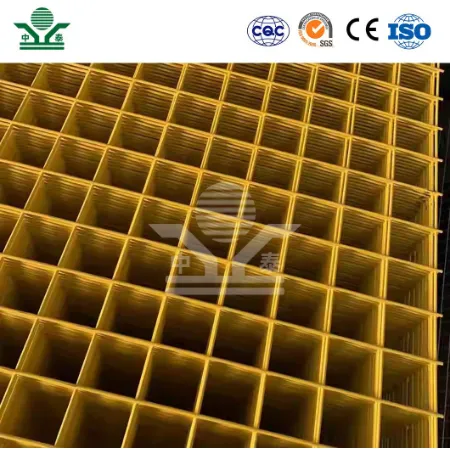

Understanding HDG Steel Grating Applications and Benefits

Hot-Dip Galvanized (HDG) steel grating is a versatile material widely used in various industries. It is composed of steel bars that are fused together to form a grid-like structure, which is then coated with a layer of zinc through the hot-dip galvanization process. This method enhances the steel’s resistance to rust, corrosion, and physical wear, making it suitable for both indoor and outdoor applications.

The Galvanization Process

The process of hot-dip galvanization involves immersing clean steel grating in molten zinc. The heat causes a metallurgical bond between the zinc and the steel, leading to a thick, well-adhered coating. The result is a surface that can withstand environmental factors such as moisture, humidity, and chemical exposure. This long-lasting protection significantly extends the life of steel grating, making it a cost-effective solution.

Key Advantages of HDG Steel Grating

1. Corrosion Resistance The primary benefit of HDG steel grating is its enhanced corrosion resistance. It can endure harsh weather conditions and is less susceptible to rust, making it ideal for use in coastal environments or areas with high humidity.

2. Durability HDG steel grating is known for its durability. The robust construction of the grating can support heavy loads and is designed to withstand significant dynamic forces. This makes it suitable for applications in industrial settings where heavy equipment or foot traffic is common.

3. Safety Features Many HDG steel grating products are designed with non-slip surfaces to enhance safety in workplaces. The open design allows for better drainage, reducing the risk of water accumulation, which can lead to slip hazards.

4. Cost-Effectiveness Although the initial cost of HDG steel grating might be higher than that of untreated steel, the long-term savings due to reduced maintenance and replacement costs make it a viable investment. With a lifespan that can exceed 50 years, businesses benefit significantly from using HDG grating over time.

hdg steel grating

5. Versatility HDG steel grating is highly versatile and can be customized to fit a variety of applications. It is used in platforms, walkways, stair treads, and as trench covers in various industries, including construction, oil and gas, mining, and wastewater treatment.

Applications of HDG Steel Grating

The applications of HDG steel grating are extensive. In industrial settings, it is commonly used for flooring in machinery rooms, catwalks, and maintenance platforms. Its non-slip surface makes it invaluable in high-traffic areas, ensuring safe navigation for both workers and machinery.

In municipal applications, HDG steel grating is often employed in public walkways, parks, and bridges. Its ability to enhance drainage while maintaining structural integrity makes it an excellent choice for these areas, particularly in regions prone to heavy rainfall.

Moreover, in the oil and gas sector, HDG steel grating is used for offshore platforms and storage areas, where exposure to marine environments accelerates corrosion. The galvanization process ensures that the grating maintains its integrity and performance under these challenging conditions.

Environmental Considerations

In a world increasingly focused on sustainability, HDG steel grating stands out as an environmentally friendly option. The galvanization process minimizes the need for frequent replacements, thus reducing waste. Additionally, steel is fully recyclable, making HDG grating a sustainable choice for environmentally conscious businesses.

Conclusion

In conclusion, HDG steel grating offers a unique combination of durability, safety, and versatility that makes it an essential material in various industries. Its resistance to corrosion and wear, along with its ability to perform well in demanding conditions, solidifies its status as a preferred choice for many applications. As businesses continue to seek cost-effective and sustainable building materials, HDG steel grating will remain at the forefront of industrial solutions, providing safety and performance for years to come.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.