Galvanized Steel Grating for Sale A Comprehensive Guide

When it comes to industrial applications, the choice of materials can significantly impact performance and safety. Among the myriad options available, galvanized steel grating stands out due to its durability, versatility, and resistance to corrosion. This article explores the advantages of galvanized steel grating, its various applications, and what you need to consider when purchasing it.

What is Galvanized Steel Grating?

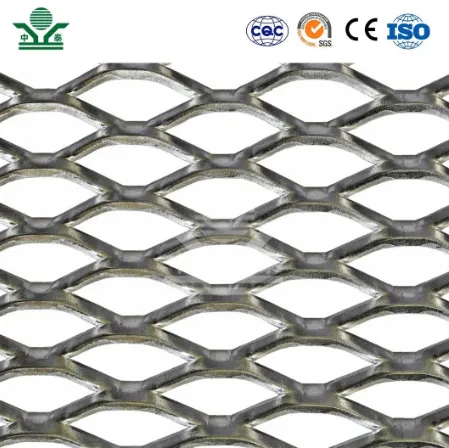

Galvanized steel grating is a flooring solution made from steel bars that are hot-dip galvanized to protect against rust and corrosion. The grating is designed with a series of open spaces that allow for ventilation, drainage, and light penetration, making it an ideal choice for various environments, including industrial plants, walkways, and platforms.

Advantages of Galvanized Steel Grating

1. Corrosion Resistance The galvanization process involves coating the steel with a layer of zinc, which acts as a protective barrier against moisture, chemicals, and other corrosive elements. This feature is particularly crucial in environments exposed to harsh weather conditions or corrosive substances.

2. Durability Galvanized steel grating is built to last. Its robust construction can withstand heavy loads and high foot traffic, making it suitable for warehouses, factories, and construction sites.

3. Safety The open design of grating allows for natural drainage, reducing the risk of slips and falls due to water accumulation. Additionally, the lightweight yet sturdy nature of the grating facilitates easy installation and maintenance, enhancing overall safety in workplaces.

4. Cost-Effectiveness While the initial cost might be higher than some alternative materials, the longevity and low maintenance requirements of galvanized steel grating offer substantial savings in the long run. Its resistance to wear and corrosion minimizes replacement and repair costs.

5. Versatility Galvanized steel grating is available in various sizes, shapes, and load ratings, allowing it to be customized for specific applications. Whether you need a grating for pedestrian walkways or heavy machinery platforms, there is a suitable option available.

Applications of Galvanized Steel Grating

galvanized steel grating for sale

Galvanized steel grating is used in a wide range of applications, including

- Industrial Flooring Its load-bearing capabilities make it suitable for factory floors, storage areas, and assembly lines. - Surrounds and Walkways Grating provides a safe surface for walkways and steps, particularly in outdoor or high-traffic areas. - Platforms and Catwalks Elevated structures rely on galvanized steel grating for stable flooring that can withstand heavy usage. - Drainage Systems The open structure allows for effective water drainage, preventing pooling and flooding in industrial sites.

What to Consider When Purchasing Galvanized Steel Grating

1. Load Requirements Different applications will have varying load requirements. It is important to select grating that can safely support the anticipated weight.

2. Bar Spacing and Size The spacing between the bars can impact safety and functionality. Select a pattern that meets your specific needs, considering factors like foot traffic and material flow.

3. Thickness and Width The thickness and width of the grating affect its load-bearing capacity. Ensure you choose the right dimensions for your specific application.

4. Finish and Coating While hot-dip galvanization is common, other finishing options may be available, depending on the environment and specific needs.

5. Supplier Reputation Choose a reputable supplier who can provide quality products and expert advice. Check customer reviews and product certifications to ensure you are making a sound investment.

Conclusion

Galvanized steel grating is a reliable and versatile solution for various industrial applications. Its durability, corrosion resistance, and safety features make it an ideal choice for environments that demand high performance and longevity. When purchasing galvanized steel grating, consider your specific needs and consult with suppliers to ensure you get the best product for your requirements.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.