The Versatility of Galvanized Serrated Bar Grating

Galvanized serrated bar grating is a widely utilized material in various industrial and commercial applications. It combines strength, durability, and anti-slip properties, making it an ideal choice for environments where safety and functionality are critical.

Composition and Manufacturing Process

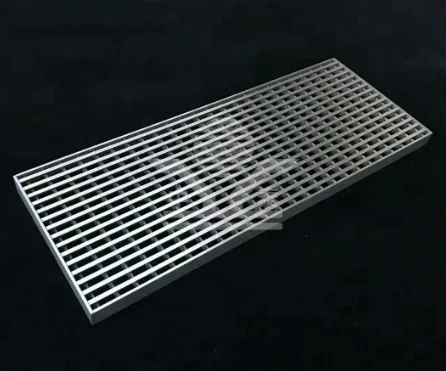

Galvanized serrated bar grating is made from steel bars, which are welded together to form a lattice of load-bearing elements. The term serrated refers to the notched edges of the bearing bars, which enhance traction and provide a slip-resistant surface. The galvanization process involves coating the steel with a layer of zinc, which protects it from corrosion and extends its lifespan, especially in harsh environments or where exposure to moisture is common.

The manufacturing process of this grating typically begins with cutting the steel into specified widths and thicknesses. The bars are then welded together in a grid formation, ensuring a strong and stable structure. After welding, the entire assembly is subjected to hot-dip galvanization, where it is submerged in molten zinc. This results in a thick, protective coating that adheres well to the steel, providing a robust barrier against rust and degradation.

Applications

Galvanized serrated bar grating is found in a multitude of applications across various sectors. Its primary uses include

1. Walkways and Platforms The anti-slip surface makes this grating ideal for walkways, platforms, and staging areas. It reduces the risk of slips and falls, particularly in wet or oily environments where traditional flooring materials might be inadequate.

2. Industrial Environments Factories, warehouses, and manufacturing plants often use serrated bar grating for flooring over pits or as covers for drainage systems. Its robust design can support heavy loads, allowing it to be used in areas with heavy machinery and equipment.

3. Outdoor Installations The weather-resistant properties of galvanized steel make this type of grating suitable for outdoor applications. It can be utilized in parks, bridges, and other outdoor structures where durability is essential.

4. Safety Grating In facilities such as chemical plants, oil refineries, and power stations, safety is paramount. The serrated design not only enhances grip but also allows debris to fall through, preventing accumulation that could lead to hazards.

galvanized serrated bar grating

5. Trailers and Ramps Serrated bar grating is also effective for use in mobile applications, such as ramps for loading docks and trailers. Its lightweight yet sturdy construction offers a reliable solution for transporting goods.

Advantages

The advantages of utilizing galvanized serrated bar grating are numerous.

- Enhanced Safety The serrated surface significantly reduces slip hazards, making it an excellent choice for environments where safety is a concern.

- Corrosion Resistance The galvanization process ensures longevity and resistance to rust, which is crucial in outdoor or humid conditions.

- Low Maintenance Compared to other flooring options, galvanized grating requires minimal maintenance, leading to cost savings over time.

- Customizable Galvanized serrated bar grating can be customized to fit specific needs regarding size, load capacity, and spacing between bars. This versatility means it can be tailored for various projects and applications.

- Environmentally Friendly Steel is recyclable, and using galvanized materials can contribute to sustainability efforts within construction and industry.

Conclusion

In summary, galvanized serrated bar grating stands out as a reliable and versatile solution for a multitude of applications. Its combination of strength, slip resistance, and longevity makes it a preferred choice in industrial settings and beyond. As safety standards continue to evolve, and the demand for durable materials increases, galvanized serrated bar grating will undoubtedly play a pivotal role in various construction and manufacturing projects. By investing in quality grating solutions, businesses can enhance safety, reduce maintenance costs, and ultimately contribute to a more efficient and secure working environment.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.