Understanding Galvanized Serrated Bar Grating Applications and Benefits

Galvanized serrated bar grating is a versatile and durable product widely used in various industries for floor systems, walkways, and platforms. This type of grating is crafted from high-strength steel bars, which are spaced evenly apart to form a grid. The serrated feature refers to the unique design of the bearing bars, which have a series of cutouts along their length. This design enhances grip and slip resistance, making it an ideal choice for environments requiring safety and efficiency.

One of the primary benefits of galvanized serrated bar grating is its exceptional durability. The galvanization process involves coating the steel with a layer of zinc, providing a protective barrier against moisture, corrosion, and rust. This feature is especially advantageous in harsh environments, such as chemical plants, waste treatment facilities, and outdoor settings. The longevity of galvanized grating significantly reduces maintenance costs and replacement frequency, which is a critical consideration for businesses looking to maximize their investment.

Additionally, the serrated surface of the grating offers superior traction compared to standard flat bar grating. The unique design minimizes the risk of slips and falls, thereby enhancing workplace safety. This is particularly important in industries such as manufacturing, construction, and food processing, where employees often work in wet or oily conditions. The increased safety features of serrated grating can lead to fewer accidents, lower insurance premiums, and a more productive workforce.

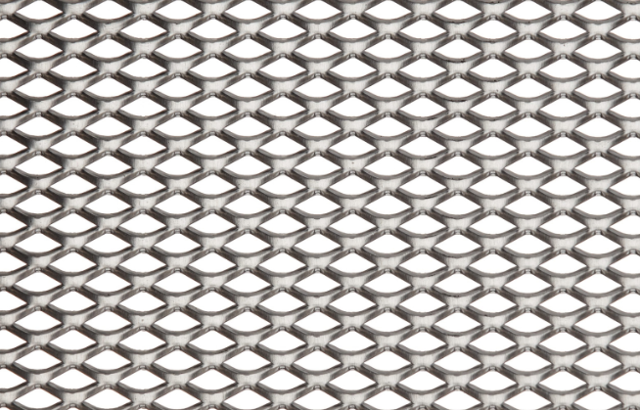

galvanized serrated bar grating

Galvanized serrated bar grating is also incredibly versatile. It can be customized to fit a wide range of applications, including but not limited to, drainage covers, walkways, and stair treads. It is available in various thicknesses, widths, and lengths, allowing for easy integration into existing structures. Furthermore, it can be fabricated to meet specific load requirements, making it suitable for heavy-duty applications.

Another important aspect of galvanized serrated bar grating is its lightweight nature, which simplifies installation. The ease of handling and installation reduces labor costs and downtime during construction and maintenance projects. The open design of the grating also allows for excellent drainage, reducing the accumulation of water or debris that can lead to hazardous conditions. The combination of lightweight construction, easy installation, and efficient drainage makes it an ideal choice for a plethora of commercial and industrial settings.

Environmental considerations are increasingly becoming important in today's construction practices. Galvanized serrated bar grating is made from recyclable materials, making it a more sustainable choice. Additionally, its long life span contributes to reduced resource consumption over time, aligning with the growing emphasis on eco-friendly products in the construction industry.

In conclusion, galvanized serrated bar grating presents a compelling choice for industries seeking durability, safety, and versatility. Its corrosion-resistant properties, slip-resistant surface, and ease of installation make it a smart investment for diverse applications. As more industries recognize the benefits of using advanced materials like galvanized serrated bar grating, its popularity is expected to continue growing. By choosing this type of grating, businesses can not only enhance workplace safety and efficiency but also contribute to sustainable practices in their operations. Whether used in industrial, commercial, or even residential applications, galvanized serrated bar grating stands out as a reliable and functional choice.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.