1 月 . 23, 2025 03:08

Back to list

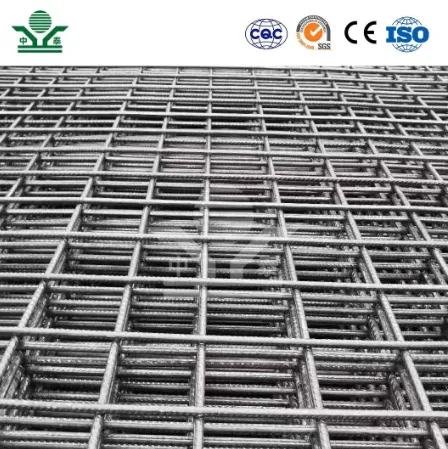

floor forge walkway steel galvanised grating

When designing a robust walkway or industrial flooring solution, the choice of material can significantly impact both the functionality and longevity of the structure. Galvanised steel grating stands out as a superior option, renowned for its durability and versatility in various environments. The combination of its strength, corrosion resistance, and low-maintenance properties makes it an ideal choice for a range of applications.

Authoritativeness in the realm of industrial flooring is often demonstrated through case studies and testimonials from industries that have utilized galvanised steel grating successfully. A compelling body of evidence from sectors such as manufacturing, transportation, and chemical processing highlights how this material has met and exceeded safety and performance expectations. It is not uncommon to find case studies detailing scenarios where other materials failed, leading to costly repairs and downtime, while galvanised steel grating continued to perform optimally. Reliability is another key factor that makes galvanised steel grating a go-to option for floor forge walkway solutions. It can withstand extreme temperatures and environmental conditions, from icy cold to blazing heat, without warping or deteriorating. This resilience, coupled with its predictable performance across different settings, allows planners and engineers to rely on it for diverse applications, from pedestrian pathways in urban settings to heavy-duty industrial platforms. Through years of innovation and practical application, galvanised steel grating has emerged as a leader in flooring solutions. Its proven track record of performance in challenging environments, combined with a lower total cost of ownership, makes it a strategic choice for companies seeking efficiency, safety, and sustainability in their infrastructure investments. Users benefit not only from the tangible qualities of strength and longevity but also from the peace of mind that comes with knowing they are using a product that meets the high standards required in today’s industrial landscape. In conclusion, when selecting a floor forge walkway material, galvanised steel grating offers a blend of reliability, safety, and economic advantages. Its unique properties allow it to serve a variety of industrial needs while delivering assurance in quality and performance—attributes highly cherished by those who prioritize safety and durability in their operations. With galvanised steel grating as part of the infrastructure, industries become better equipped to face both immediate challenges and future demands.

Authoritativeness in the realm of industrial flooring is often demonstrated through case studies and testimonials from industries that have utilized galvanised steel grating successfully. A compelling body of evidence from sectors such as manufacturing, transportation, and chemical processing highlights how this material has met and exceeded safety and performance expectations. It is not uncommon to find case studies detailing scenarios where other materials failed, leading to costly repairs and downtime, while galvanised steel grating continued to perform optimally. Reliability is another key factor that makes galvanised steel grating a go-to option for floor forge walkway solutions. It can withstand extreme temperatures and environmental conditions, from icy cold to blazing heat, without warping or deteriorating. This resilience, coupled with its predictable performance across different settings, allows planners and engineers to rely on it for diverse applications, from pedestrian pathways in urban settings to heavy-duty industrial platforms. Through years of innovation and practical application, galvanised steel grating has emerged as a leader in flooring solutions. Its proven track record of performance in challenging environments, combined with a lower total cost of ownership, makes it a strategic choice for companies seeking efficiency, safety, and sustainability in their infrastructure investments. Users benefit not only from the tangible qualities of strength and longevity but also from the peace of mind that comes with knowing they are using a product that meets the high standards required in today’s industrial landscape. In conclusion, when selecting a floor forge walkway material, galvanised steel grating offers a blend of reliability, safety, and economic advantages. Its unique properties allow it to serve a variety of industrial needs while delivering assurance in quality and performance—attributes highly cherished by those who prioritize safety and durability in their operations. With galvanised steel grating as part of the infrastructure, industries become better equipped to face both immediate challenges and future demands.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP