1 月 . 24, 2025 03:07

Back to list

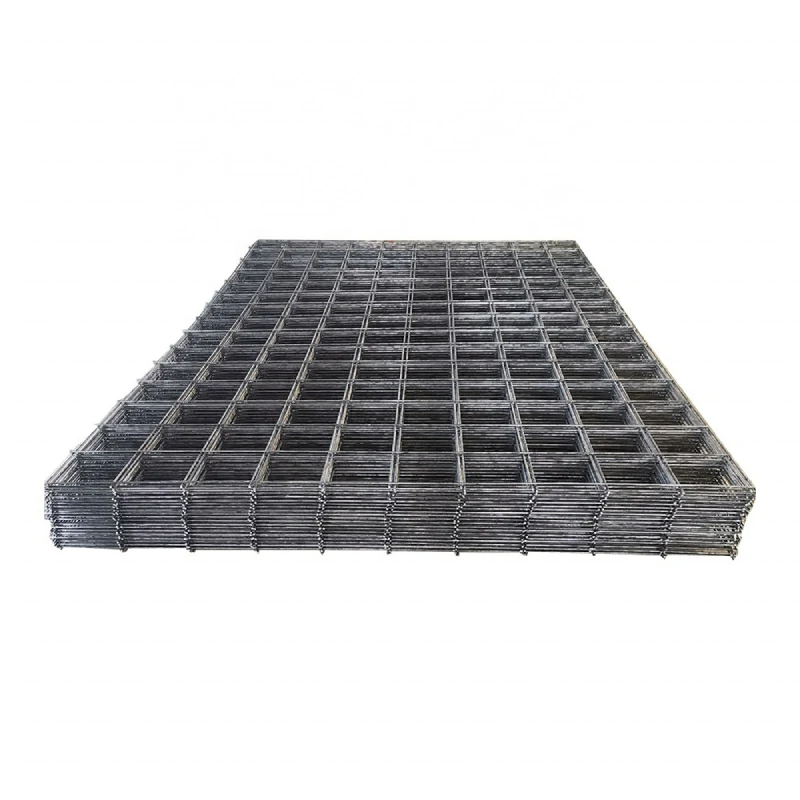

flat bar grating

When discussing industrial flooring solutions, flat bar grating emerges as a front-runner due to its remarkable balance of practicality, durability, and cost-effectiveness. Known for its unique structural design, flat bar grating finds relevance in a variety of industrial and commercial applications, offering functional excellence interwoven with unparalleled safety features.

Authors of significant industrial design textbooks highlight another compelling aspect of flat bar grating its ease of installation and maintenance. The modular nature of flat bar grating sections allows for quick assembly, minimizing downtime during installation. A seasoned construction engineer once shared insights on how projects benefited from the swift installation, keeping operations on schedule and within budget. Maintenance, another pivotal factor, benefits from the open grid structure, making cleaning efficient and reducing the build-up of debris that could impair operation over time. This contributes credibly to long-term cost savings and operational efficiency. For businesses aiming to achieve sustainability through their infrastructure, flat bar grating also offers an environmentally friendly option. Most grating materials are recyclable, aligning with global efforts toward reduced industrial waste. This feature enhances the environmental trustworthiness of organizations opting for flat bar grating, highlighting a commitment to sustainable practices. Reflecting on market trends, industry leaders prioritize authentic customer satisfaction, which flat bar grating delivers robustly through its proven performance and strategic advantages. Businesses consistently report improved operational environments and decreased incident rates, reinforcing the trust placed in these products by operations managers and safety inspectors alike. In conclusion, flat bar grating is more than just a flooring material; it's a comprehensive solution addressing critical industrial needs while supporting sustainability goals. It embodies a synergy of expertise and experience, underpinned by a track record of authority in safety and design. As industries evolve, investing in flat bar grating is not merely about meeting current requirements but preparing for future challenges with a trusted and well-regarded solution.

Authors of significant industrial design textbooks highlight another compelling aspect of flat bar grating its ease of installation and maintenance. The modular nature of flat bar grating sections allows for quick assembly, minimizing downtime during installation. A seasoned construction engineer once shared insights on how projects benefited from the swift installation, keeping operations on schedule and within budget. Maintenance, another pivotal factor, benefits from the open grid structure, making cleaning efficient and reducing the build-up of debris that could impair operation over time. This contributes credibly to long-term cost savings and operational efficiency. For businesses aiming to achieve sustainability through their infrastructure, flat bar grating also offers an environmentally friendly option. Most grating materials are recyclable, aligning with global efforts toward reduced industrial waste. This feature enhances the environmental trustworthiness of organizations opting for flat bar grating, highlighting a commitment to sustainable practices. Reflecting on market trends, industry leaders prioritize authentic customer satisfaction, which flat bar grating delivers robustly through its proven performance and strategic advantages. Businesses consistently report improved operational environments and decreased incident rates, reinforcing the trust placed in these products by operations managers and safety inspectors alike. In conclusion, flat bar grating is more than just a flooring material; it's a comprehensive solution addressing critical industrial needs while supporting sustainability goals. It embodies a synergy of expertise and experience, underpinned by a track record of authority in safety and design. As industries evolve, investing in flat bar grating is not merely about meeting current requirements but preparing for future challenges with a trusted and well-regarded solution.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP