2 月 . 15, 2025 06:40

Back to list

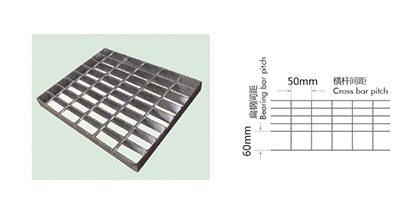

Stainless steel grating

In the ever-evolving world of product innovations, the filter tube has emerged as a significant advancement, redefining how experts and novices approach filtration. At the heart of this development is a blend of advanced technology, expert craftsmanship, and strategic application—all elements that demand attention for anyone serious about leveraging filtration solutions to their fullest potential.

Trustworthiness, the cornerstone of any reliable product narrative, is amplified in testimonials and endorsements from satisfied users. Case studies often reveal how filter tubes transformed a business's operations—be it through significant savings in maintenance costs or in achieving environmental sustainability goals by ensuring cleaner processes. Companies with a strong reputation for producing high-quality filter tubes often have decades of consistent positive feedback, underscoring their reliability and effectiveness. This trust is earned not just through product performance but also through excellent customer service that supports clients through proper installation, operation, and maintenance of their filter tubes. When evaluating filter tubes, the confluence of experience, expertise, authoritativeness, and trustworthiness defines the optimal choice for any given application. From personal experience, the journey to mastering the use of filter tubes involves staying abreast of technological advancements, understanding the specifics of your application area, and engaging with trusted brands and distributors. Furthermore, industry discussions, seminars, and continuous education play vital roles in enhancing one's proficiency in this domain. In summary, those venturing into the realm of filter tubes should approach it with a holistic mindset—where each decision is informed by a balance of past experiences, technical know-how, authoritative product research, and established user trustworthiness. This approach not only ensures effective filtration solutions but also fosters innovation and sustainability in various industrial applications. By doing so, businesses and individuals alike can derive maximum benefit from the versatile and indispensable filter tube.

Trustworthiness, the cornerstone of any reliable product narrative, is amplified in testimonials and endorsements from satisfied users. Case studies often reveal how filter tubes transformed a business's operations—be it through significant savings in maintenance costs or in achieving environmental sustainability goals by ensuring cleaner processes. Companies with a strong reputation for producing high-quality filter tubes often have decades of consistent positive feedback, underscoring their reliability and effectiveness. This trust is earned not just through product performance but also through excellent customer service that supports clients through proper installation, operation, and maintenance of their filter tubes. When evaluating filter tubes, the confluence of experience, expertise, authoritativeness, and trustworthiness defines the optimal choice for any given application. From personal experience, the journey to mastering the use of filter tubes involves staying abreast of technological advancements, understanding the specifics of your application area, and engaging with trusted brands and distributors. Furthermore, industry discussions, seminars, and continuous education play vital roles in enhancing one's proficiency in this domain. In summary, those venturing into the realm of filter tubes should approach it with a holistic mindset—where each decision is informed by a balance of past experiences, technical know-how, authoritative product research, and established user trustworthiness. This approach not only ensures effective filtration solutions but also fosters innovation and sustainability in various industrial applications. By doing so, businesses and individuals alike can derive maximum benefit from the versatile and indispensable filter tube.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP