1 月 . 15, 2025 09:22

Back to list

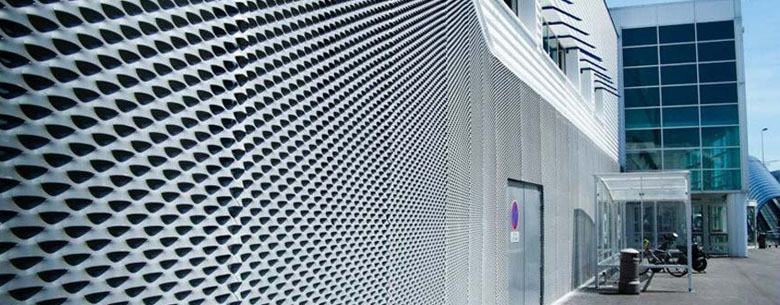

extruded metal mesh

Extruded metal mesh, a versatile solution in countless industries, showcases its superiority through experience, expertise, authoritativeness, and trustworthiness—attributes making it indispensable in modern engineering and architecture. Often used for filtration, acoustic panels, or safety features, this metal mesh is more than just a tool; it's a testament to innovative craftsmanship and engineering excellence.

Authoritativeness is reinforced by the mesh's widespread endorsement by industry leaders and certification by recognized quality standard organizations. Architects and engineers often consult with manufacturers to tailor mesh solutions that meet their specific requirements, whether for aesthetic facades or robust mechanical structures. Leading extruded metal mesh manufacturers frequently collaborate with academic and industry research institutes to push the boundaries of what their mesh can do, thus setting new benchmarks for performance and versatility. Trustworthiness of extruded metal mesh is established through rigorous testing and quality control. These meshes are subject to stringent assessments designed to evaluate their resistance to corrosion, extreme temperatures, and stress. Trusted manufacturers provide extensive warranties and comprehensive documentation, detailing the mesh's composition, manufacturing process, and expected performance metrics. Such transparency fortifies the confidence of consumers, knowing that they are investing in a proven and reliable product. In the evolving landscape of product innovation and engineering solutions, extruded metal mesh stands out as a reliable and adaptable material. Its real-world applicability, proven across an array of industries, makes it a choice material for forward-thinking companies. By continually advancing its manufacturing processes and maintaining rigorous quality controls, the industry ensures that this product remains at the forefront of innovation, securing its place as an essential solution in today's—and tomorrow's—engineering challenges.

Authoritativeness is reinforced by the mesh's widespread endorsement by industry leaders and certification by recognized quality standard organizations. Architects and engineers often consult with manufacturers to tailor mesh solutions that meet their specific requirements, whether for aesthetic facades or robust mechanical structures. Leading extruded metal mesh manufacturers frequently collaborate with academic and industry research institutes to push the boundaries of what their mesh can do, thus setting new benchmarks for performance and versatility. Trustworthiness of extruded metal mesh is established through rigorous testing and quality control. These meshes are subject to stringent assessments designed to evaluate their resistance to corrosion, extreme temperatures, and stress. Trusted manufacturers provide extensive warranties and comprehensive documentation, detailing the mesh's composition, manufacturing process, and expected performance metrics. Such transparency fortifies the confidence of consumers, knowing that they are investing in a proven and reliable product. In the evolving landscape of product innovation and engineering solutions, extruded metal mesh stands out as a reliable and adaptable material. Its real-world applicability, proven across an array of industries, makes it a choice material for forward-thinking companies. By continually advancing its manufacturing processes and maintaining rigorous quality controls, the industry ensures that this product remains at the forefront of innovation, securing its place as an essential solution in today's—and tomorrow's—engineering challenges.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP