The Versatility of Punched Metal Sheets

Punched metal sheets are an essential component in modern manufacturing and architecture, renowned for their versatility and functional attributes. These sheets are created by punching holes or patterns into metal, offering a multitude of applications across various industries. This article delves into the characteristics, advantages, and myriad uses of punched metal sheets.

What Are Punched Metal Sheets?

Punched metal sheets are manufactured from a variety of metals, including steel, aluminum, and brass. The punching process involves using a specialized tool that forces a die through the metal, resulting in clean, precise holes or designs. The dimensions, spacing, and shape of the holes can be customized based on specific requirements, making punched metal sheets highly adaptable.

Key Characteristics

One of the most distinguishing features of punched metal sheets is their strength-to-weight ratio. They are sturdy yet lightweight, making them ideal for applications where reducing weight is crucial. Depending on the thickness of the sheet and the type of metal used, punched sheets can maintain structural integrity while providing excellent durability.

Moreover, the perforated patterns allow for airflow and ventilation, which is particularly advantageous in environments requiring adequate cooling. The customizability of the hole patterns can also aid in aesthetic design, giving architects and designers the freedom to innovate while maintaining functionality.

Advantages of Punched Metal Sheets

1. Cost-Effectiveness Punched metal sheets are economical, especially when produced in large quantities. The efficiency of the punching process contributes to lower production costs compared to other methods of creating perforated materials.

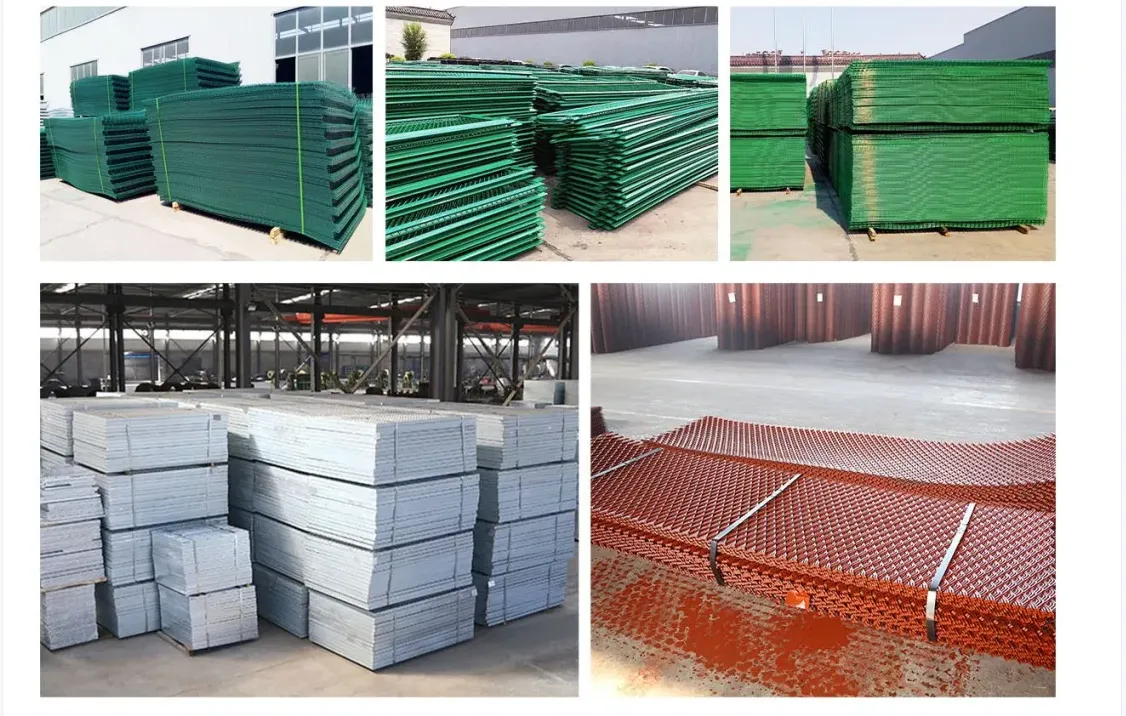

punched metal sheets

2. Lightweight yet Durable The combination of strength and reduced weight allows for ease in handling, installation, and transportation. This is particularly important in industries like automotive and construction, where every kilogram counts.

3. Customizable Design The ability to alter hole sizes, shapes, and patterns makes punched metal sheets a favorite among manufacturers and designers alike. This customization can be tailored to meet specific functional requirements or aesthetic preferences.

4. Versatility These sheets are widely used in numerous applications, from building facades and railings to filter designs and soundproofing applications. Their use is not limited to a single sector but spans architecture, automotive, aerospace, and industrial manufacturing.

Applications of Punched Metal Sheets

The applications of punched metal sheets are vast and diverse. In architecture, they are often used for decorative facades, sunshades, and cladding systems, where both aesthetic appeal and functional ventilation are desired. In the automotive industry, they are utilized in various parts such as grilles and interior trim where weight reduction is critical without sacrificing strength.

Punched metal sheets also find applications in consumer products, such as kitchen appliances, where they provide both an attractive design and necessary functionality. Furthermore, they are invaluable in filtration systems, allowing for the separation of particles while maintaining a lightweight profile.

In industrial settings, these sheets can serve as safety barriers, machine guards, and storage solutions, all while allowing visibility and airflow. The construction of exhibition booths and displays benefits from the modularity and visual appeal of punched metal sheets, showcasing the union of form and function.

Conclusion

Punched metal sheets represent a remarkable synthesis of versatility, durability, and design potential. Their ability to meet a wide range of industrial needs while providing aesthetic value underscores their significance in contemporary manufacturing and architecture. As industries continue to evolve, the applications and innovations surrounding punched metal sheets will undoubtedly expand further, reaffirming their status as a cornerstone in the world of metalworking.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.