1 月 . 25, 2025 21:18

Back to list

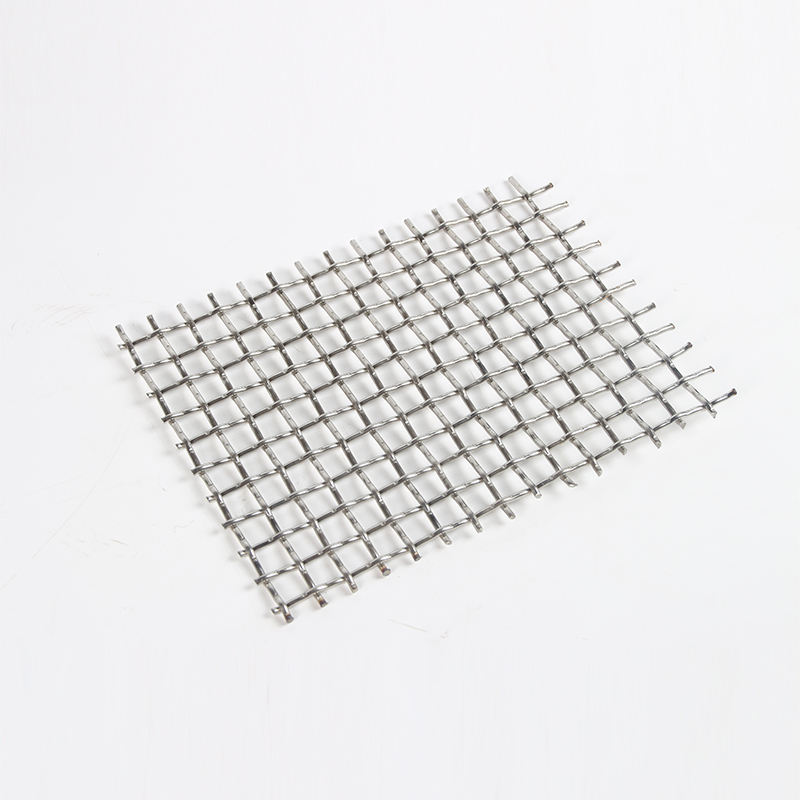

expanded metal walkway mesh

Exploring the realm of expanded metal walkway mesh unveils a product praised not only for its structural robustness but also for its multifaceted applications across various industries. Its unique characteristics stem from a manufacturing process that intricately expands and stretches metal sheets, resulting in a lightweight yet high strength-per-weight ratio material. This remarkable feature positions expanded metal mesh as an optimal choice in the realms of safety, efficiency, and innovation.

Expertise in handling and installing expanded metal walkway mesh is essential. It requires a comprehension not only of its material properties but also of the specifics surrounding its optimal use scenarios. This specialized knowledge ensures enhanced longevity and performance, thus demanding attention to detail and precision during installation. Fabrication professionals armed with years of experience provide a trustworthy source of guidance, helping businesses select the appropriate specifications tailored to their unique needs. Authoritative organizations and industry professionals continue to validate the practical benefits of expanded metal products. Compliance with stringent safety and quality standards is crucial. Products undergo rigorous testing to certify their load-bearing capacity, slip resistance, and corrosion resistance, ensuring they meet or surpass the demanding requirements set forth by international safety standards, such as those stipulated by OSHA or EN. The consistent adherence to these criteria confirms expanded metal walkway mesh as a reliable solution embraced by numerous industries. To maintain trustworthiness, manufacturers and suppliers must establish transparency in their operations, presenting clear information regarding the product’s origin, quality assurances, and performance data. This transparency bolsters confidence for consumers and industrial users, assuring them of the material’s dependability in critical applications. The journey into utilizing expanded metal walkway mesh embodies a fusion of historical expertise, contemporary innovation, and practical application. As industries evolve and place an increasing emphasis on safety, sustainability, and design, this extraordinary material continues to stand at the forefront, proving itself not merely as a component in a structural framework but as a fundamental element in shaping the modern industrial and architectural landscapes.

Expertise in handling and installing expanded metal walkway mesh is essential. It requires a comprehension not only of its material properties but also of the specifics surrounding its optimal use scenarios. This specialized knowledge ensures enhanced longevity and performance, thus demanding attention to detail and precision during installation. Fabrication professionals armed with years of experience provide a trustworthy source of guidance, helping businesses select the appropriate specifications tailored to their unique needs. Authoritative organizations and industry professionals continue to validate the practical benefits of expanded metal products. Compliance with stringent safety and quality standards is crucial. Products undergo rigorous testing to certify their load-bearing capacity, slip resistance, and corrosion resistance, ensuring they meet or surpass the demanding requirements set forth by international safety standards, such as those stipulated by OSHA or EN. The consistent adherence to these criteria confirms expanded metal walkway mesh as a reliable solution embraced by numerous industries. To maintain trustworthiness, manufacturers and suppliers must establish transparency in their operations, presenting clear information regarding the product’s origin, quality assurances, and performance data. This transparency bolsters confidence for consumers and industrial users, assuring them of the material’s dependability in critical applications. The journey into utilizing expanded metal walkway mesh embodies a fusion of historical expertise, contemporary innovation, and practical application. As industries evolve and place an increasing emphasis on safety, sustainability, and design, this extraordinary material continues to stand at the forefront, proving itself not merely as a component in a structural framework but as a fundamental element in shaping the modern industrial and architectural landscapes.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP