1 月 . 20, 2025 12:51

Back to list

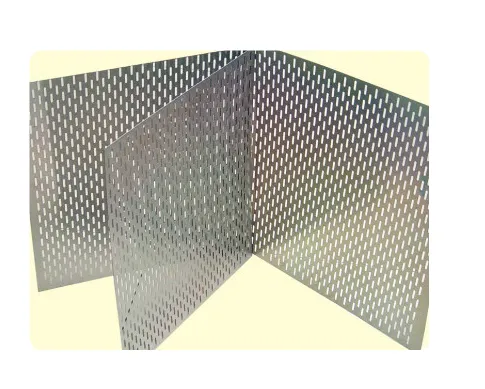

steel grating pics

Exploring the intricacies of expanded metal mesh standard sizes can vastly improve your product knowledge and purchasing prowess. For construction professionals, architects, or do-it-yourself enthusiasts, understanding this material’s dimensions, applications, and benefits is crucial. Expanded metal mesh is a versatile and durable material, finding utility in various industrial and architectural applications.

A critical factor when selecting expanded metal mesh is the type of metal used. Common materials include steel, stainless steel, aluminum, and copper, each bringing complementary benefits. For instance, stainless steel meshes offer corrosion resistance, making them ideal for chemical processing or outdoor uses where weatherability is a key concern. Aluminum meshes are lightweight, making them suitable for applications where weight is a critical factor, like transportation. Delving into economic aspects, expanded metal mesh is more cost-effective compared to other metal products. The expanding process results in little to no waste, optimizing material usage and bringing additional cost savings that are attractive to budget-conscious contractors and designers. Moreover, fewer additional materials are needed for installation as it is self-reinforcing. Consulting with experts is essential when making decisions about expanded metal mesh. Their professional insights ensure selection of the appropriate size, material, and configuration based on project specifics and long-term sustainability. Furthermore, industry guidelines or standards should always be adhered to, guaranteeing structural soundness and compliance with regulatory demands. Selecting the right expanded metal mesh not only provides structural excellence but also enhances safety and aesthetic appeal, making it a prime material in both functional and decorative applications. Embracing its utilization translates to astute architectural or industrial strategies, meeting modern standards for efficiency and innovation.

A critical factor when selecting expanded metal mesh is the type of metal used. Common materials include steel, stainless steel, aluminum, and copper, each bringing complementary benefits. For instance, stainless steel meshes offer corrosion resistance, making them ideal for chemical processing or outdoor uses where weatherability is a key concern. Aluminum meshes are lightweight, making them suitable for applications where weight is a critical factor, like transportation. Delving into economic aspects, expanded metal mesh is more cost-effective compared to other metal products. The expanding process results in little to no waste, optimizing material usage and bringing additional cost savings that are attractive to budget-conscious contractors and designers. Moreover, fewer additional materials are needed for installation as it is self-reinforcing. Consulting with experts is essential when making decisions about expanded metal mesh. Their professional insights ensure selection of the appropriate size, material, and configuration based on project specifics and long-term sustainability. Furthermore, industry guidelines or standards should always be adhered to, guaranteeing structural soundness and compliance with regulatory demands. Selecting the right expanded metal mesh not only provides structural excellence but also enhances safety and aesthetic appeal, making it a prime material in both functional and decorative applications. Embracing its utilization translates to astute architectural or industrial strategies, meeting modern standards for efficiency and innovation.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP