1 月 . 15, 2025 09:54

Back to list

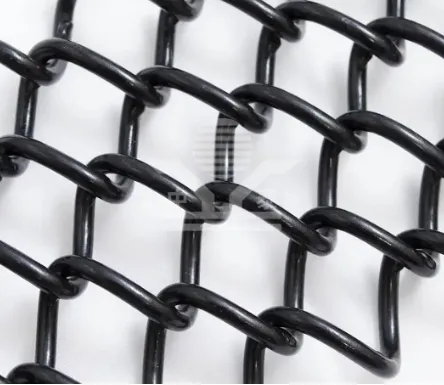

expanded metal mesh sheet

Expanded metal mesh sheets represent a key material in numerous industries due to their versatility, durability, and cost-effectiveness. For businesses looking to innovate or upgrade their processes, understanding the fine details of these sheets can greatly impact functionality and effectiveness in applications.

From an expertise standpoint, the choice of material significantly influences the overall performance in specific applications. While carbon steel offers superior strength for heavy-load applications, aluminum stands out for projects requiring additional corrosion resistance and conductivity. Stainless steel embodied corrosion resistance is indispensable in environments exposed to water and chemicals. Moreover, expanded metal mesh sheets contribute to energy efficiency in architectural and industrial applications. By facilitating natural ventilation and light penetration, they help reduce reliance on artificial systems, which in turn, minimizes energy consumption. This attribute is particularly valued in green building initiatives aiming for sustainable construction and operation. For industries transitioning into greener practices, it’s notable that the manufacturing process of expanded metal mesh sheets is aligned with environmental objectives. The zero-waste production principle not only conserves valuable resources but also reduces the material's carbon footprint, aligning with global sustainability goals. A crucial aspect of selecting the right expanded metal mesh sheet lies in choosing a trustworthy supplier committed to quality and compliance with industry standards. Leading suppliers provide certification and comprehensive support to ensure that the materials meet all required specifications for safety and performance. By collaborating with reputable suppliers, businesses can secure materials that not only fulfill technical requirements but also uphold the integrity and reputation of their projects. In conclusion, expanded metal mesh sheets are more than just a construction material; they are a testament to engineering efficiency and sustainability. Whether it’s driving innovation in industrial practices or enhancing architectural aesthetics, the multifunctional benefits of these sheets are undeniable. Investing in high-quality expanded metal mesh sheets can therefore vastly uplift the economic and operational potential of its users across various sectors.

From an expertise standpoint, the choice of material significantly influences the overall performance in specific applications. While carbon steel offers superior strength for heavy-load applications, aluminum stands out for projects requiring additional corrosion resistance and conductivity. Stainless steel embodied corrosion resistance is indispensable in environments exposed to water and chemicals. Moreover, expanded metal mesh sheets contribute to energy efficiency in architectural and industrial applications. By facilitating natural ventilation and light penetration, they help reduce reliance on artificial systems, which in turn, minimizes energy consumption. This attribute is particularly valued in green building initiatives aiming for sustainable construction and operation. For industries transitioning into greener practices, it’s notable that the manufacturing process of expanded metal mesh sheets is aligned with environmental objectives. The zero-waste production principle not only conserves valuable resources but also reduces the material's carbon footprint, aligning with global sustainability goals. A crucial aspect of selecting the right expanded metal mesh sheet lies in choosing a trustworthy supplier committed to quality and compliance with industry standards. Leading suppliers provide certification and comprehensive support to ensure that the materials meet all required specifications for safety and performance. By collaborating with reputable suppliers, businesses can secure materials that not only fulfill technical requirements but also uphold the integrity and reputation of their projects. In conclusion, expanded metal mesh sheets are more than just a construction material; they are a testament to engineering efficiency and sustainability. Whether it’s driving innovation in industrial practices or enhancing architectural aesthetics, the multifunctional benefits of these sheets are undeniable. Investing in high-quality expanded metal mesh sheets can therefore vastly uplift the economic and operational potential of its users across various sectors.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP