1 月 . 19, 2025 04:24

Back to list

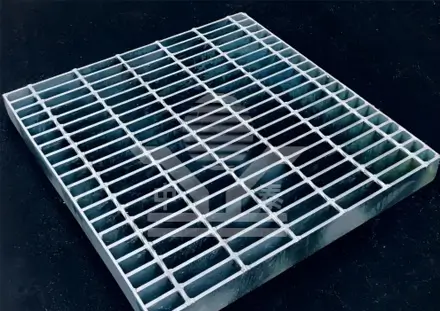

3D Galvanized Steel Material Perforated Metal Sheet for Fencing

Expanded metal mesh production stands as a vital component in a range of industrial and architectural applications, from providing structural support and security to enhancing the aesthetic appeal of a given space. Drawing from years of experience in the field and relying on state-of-the-art technology, modern production methods ensure quality and efficiency in delivering this versatile product.

Further boosting the authoritativeness of expanded metal mesh manufacturers is their commitment to research and development. By investing in innovative technologies, these companies continue to push the boundaries of what this seemingly simple product can achieve. This forward-thinking approach translates into cutting-edge solutions that meet the evolving demands of modern construction, energy, and transportation sectors. Trust in expanded metal mesh products is fostered by transparent practices and customer-centric service. Leading manufacturers offer comprehensive after-sales support, including installation guidance and maintenance advice, ensuring that the mesh delivers peak performance throughout its lifespan. Additionally, clear communication channels and responsive customer service reinforce customer confidence, establishing a strong rapport between clients and providers. Trustworthiness is further bolstered by a demonstrated track record of successful projects and satisfied clientele. Case studies and testimonials often highlight the reliability and adaptability of expanded metal mesh in challenging environments, providing potential clients with reassurance and a basis for informed decision-making. In conclusion, the production of expanded metal mesh showcases a blend of precision engineering, informed expertise, and commitment to quality. As industries and consumers alike seek reliable, sustainable solutions, this product continues to stand out with its myriad applications and consistent reliability. By aligning production with the highest standards of experience, expertise, authoritativeness, and trustworthiness, manufacturers ensure that they not only meet but exceed the expectations of a discerning market, securing their place as leaders in this ever-essential industry.

Further boosting the authoritativeness of expanded metal mesh manufacturers is their commitment to research and development. By investing in innovative technologies, these companies continue to push the boundaries of what this seemingly simple product can achieve. This forward-thinking approach translates into cutting-edge solutions that meet the evolving demands of modern construction, energy, and transportation sectors. Trust in expanded metal mesh products is fostered by transparent practices and customer-centric service. Leading manufacturers offer comprehensive after-sales support, including installation guidance and maintenance advice, ensuring that the mesh delivers peak performance throughout its lifespan. Additionally, clear communication channels and responsive customer service reinforce customer confidence, establishing a strong rapport between clients and providers. Trustworthiness is further bolstered by a demonstrated track record of successful projects and satisfied clientele. Case studies and testimonials often highlight the reliability and adaptability of expanded metal mesh in challenging environments, providing potential clients with reassurance and a basis for informed decision-making. In conclusion, the production of expanded metal mesh showcases a blend of precision engineering, informed expertise, and commitment to quality. As industries and consumers alike seek reliable, sustainable solutions, this product continues to stand out with its myriad applications and consistent reliability. By aligning production with the highest standards of experience, expertise, authoritativeness, and trustworthiness, manufacturers ensure that they not only meet but exceed the expectations of a discerning market, securing their place as leaders in this ever-essential industry.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP