1 月 . 19, 2025 03:40

Back to list

expanded metal mesh catalogue

Expanded metal mesh has become an integral component in industries ranging from construction to automotive, lauded for its versatility and durability. This guide, Expanded Metal Mesh Catalogue, aims to equip you with comprehensive insights drawn from years of hands-on experience and expert knowledge, ensuring informed decisions for your projects.

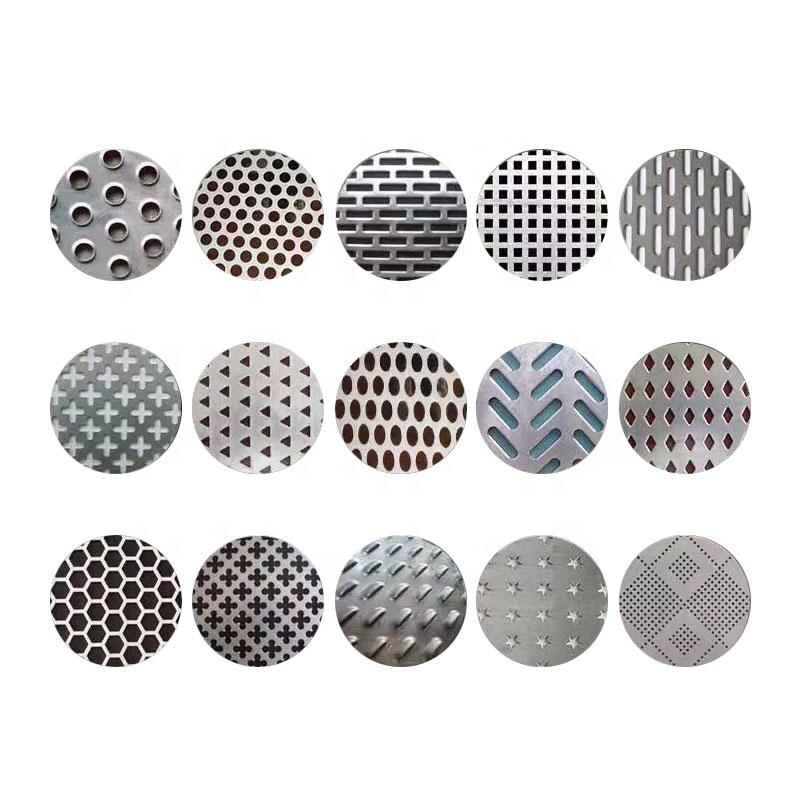

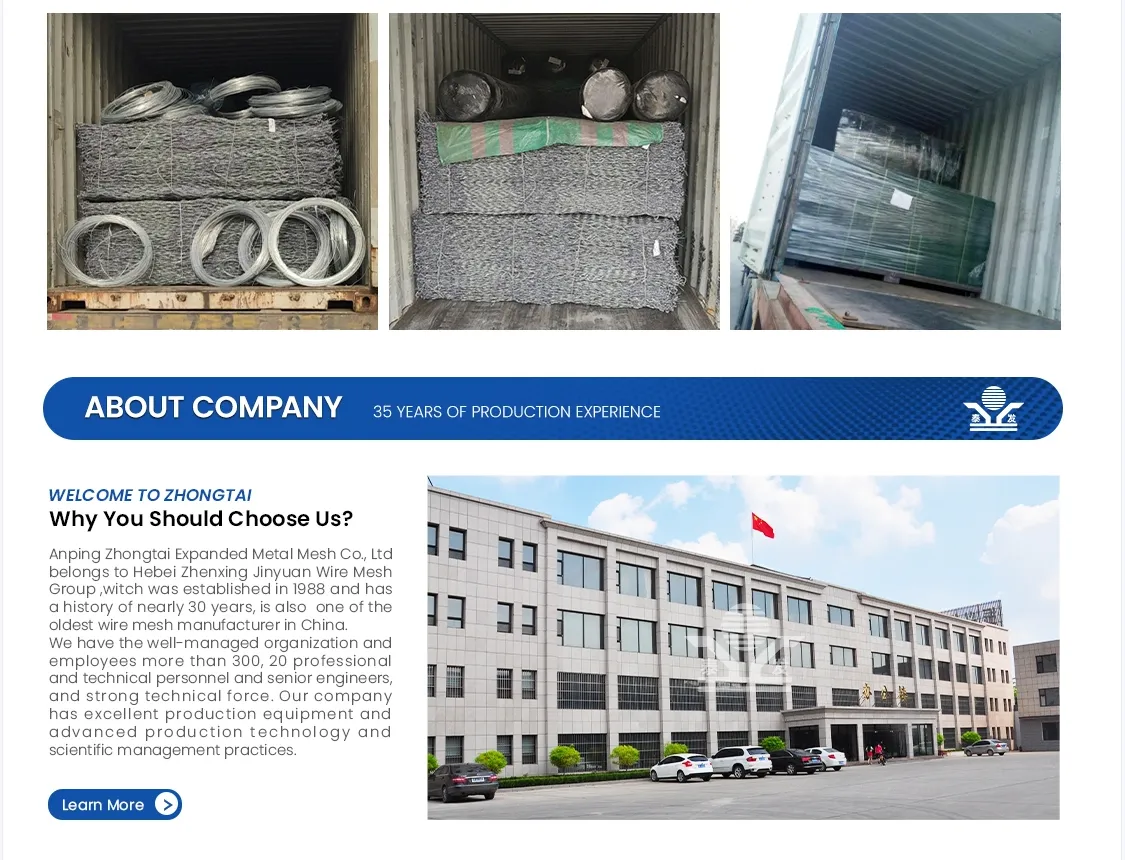

Trustworthiness in the selection of expanded metal mesh is further enhanced by its traceability. Reputable manufacturers provide detailed product documentation, including material composition and production processes. This transparency is crucial for industry professionals seeking to maintain the highest standards of accountability and quality control. In practice, the benefits of expanded metal mesh extend to ease of installation and maintenance. Its lightweight nature reduces transportation costs and simplifies handling on-site. Moreover, the material's durability withstands harsh environmental conditions, prolonging its service life with minimal upkeep. These attributes have been validated in numerous field applications, where reliability and efficiency are paramount. For architects, the aesthetic possibilities of expanded metal mesh expand creative horizons. Its three-dimensional shape adds texture and depth to building facades, contributing to innovative architectural designs. Coupled with finishes such as powder coating or anodizing, the mesh can be tailored to complement any design scheme while offering additional protection against corrosion. In conclusion, the expanded metal mesh stands as a versatile, durable, and cost-effective solution across multiple industries. The expanded metal mesh catalogue offers an array of options tailored to meet the diverse needs of modern engineering and design challenges. Drawing from extensive industry experience, a thorough understanding of product specifications, and a commitment to quality, professionals can confidently integrate expanded metal mesh into their projects, assured of performance and reliability.

Trustworthiness in the selection of expanded metal mesh is further enhanced by its traceability. Reputable manufacturers provide detailed product documentation, including material composition and production processes. This transparency is crucial for industry professionals seeking to maintain the highest standards of accountability and quality control. In practice, the benefits of expanded metal mesh extend to ease of installation and maintenance. Its lightweight nature reduces transportation costs and simplifies handling on-site. Moreover, the material's durability withstands harsh environmental conditions, prolonging its service life with minimal upkeep. These attributes have been validated in numerous field applications, where reliability and efficiency are paramount. For architects, the aesthetic possibilities of expanded metal mesh expand creative horizons. Its three-dimensional shape adds texture and depth to building facades, contributing to innovative architectural designs. Coupled with finishes such as powder coating or anodizing, the mesh can be tailored to complement any design scheme while offering additional protection against corrosion. In conclusion, the expanded metal mesh stands as a versatile, durable, and cost-effective solution across multiple industries. The expanded metal mesh catalogue offers an array of options tailored to meet the diverse needs of modern engineering and design challenges. Drawing from extensive industry experience, a thorough understanding of product specifications, and a commitment to quality, professionals can confidently integrate expanded metal mesh into their projects, assured of performance and reliability.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP