Expanded Metal Grating An Essential Solution for Industrial Needs

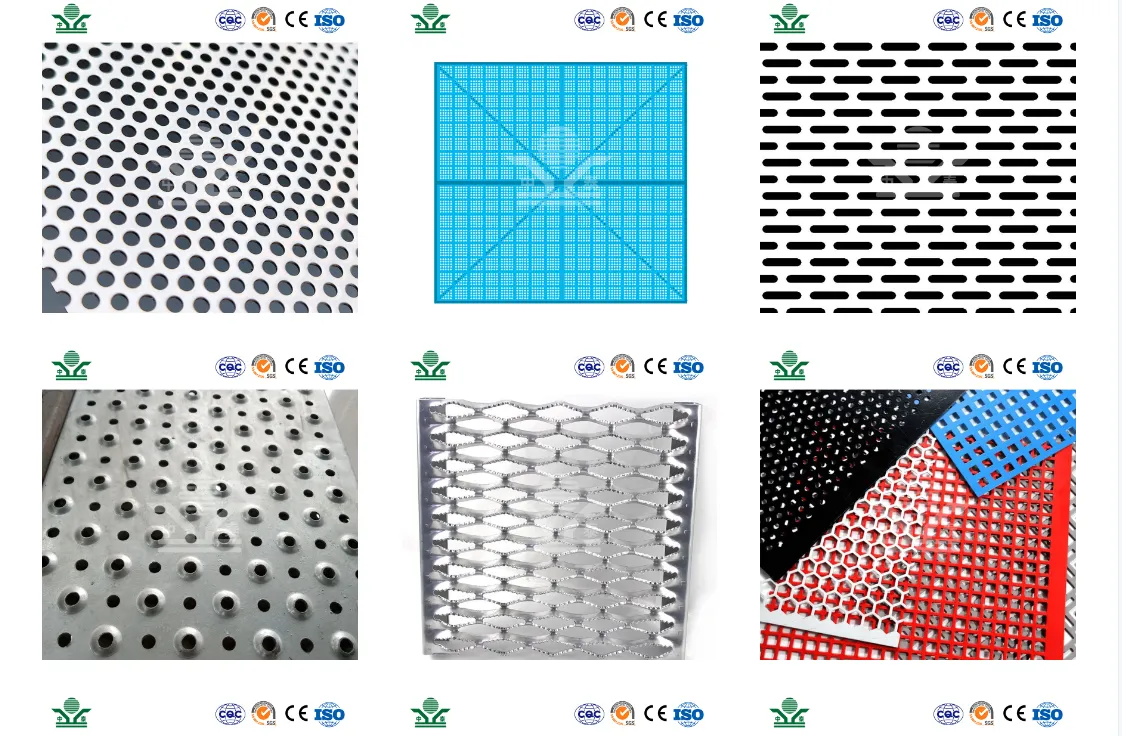

Expanded metal grating is a versatile and widely used material in various industries, owing to its strength, durability, and functionality. Created by cutting and stretching a sheet of metal, it forms a mesh-like pattern, allowing for excellent drainage and airflow. This type of grating is not only practical but also cost-effective, making it an ideal choice for industrial flooring, walkways, and platforms.

One of the primary advantages of expanded metal grating is its lightweight nature, which does not compromise its strength. The process of expansion allows the metal to retain its structural integrity while minimizing weight, making it easier to handle and install. This characteristic is particularly beneficial in industrial settings where the strength-to-weight ratio is crucial. For instance, in manufacturing plants and warehouses, the ability to create stable walkways that can support heavy loads without being overly cumbersome is invaluable.

Another notable feature of expanded metal grating is its slip-resistant surface. The unique pattern created during the expansion process provides excellent traction, which is essential in reducing workplace accidents, especially in areas exposed to liquids or mechanical operations. This safety attribute makes expanded metal grating a preferred choice in environments such as chemical plants, food processing facilities, and other industrial areas where safety is paramount.

Cost-effectiveness is another compelling reason for the popularity of expanded metal grating

. Compared to other flooring options, such as solid metal plates or composite materials, expanded metal offers a more economical solution without sacrificing quality. Its manufacturing process generates minimal waste, allowing for lower material costs while providing an effective alternative for companies seeking to optimize their budgets.expanded metal grating

Moreover, expanded metal grating is highly customizable. Available in various materials—including steel, aluminum, and copper—it can be tailored to meet specific requirements based on environmental conditions and load-bearing needs. This flexibility means businesses can procure grating that provides the ideal combination of strength, corrosion resistance, and aesthetic appeal. For outdoor applications, for instance, aluminum grating is often preferred due to its rust-resistant properties, ensuring longevity and low maintenance.

Expanded metal grating is also environmentally friendly. Its design promotes natural ventilation, which is essential for preventing the build-up of harmful vapors or gases in industrial settings. By allowing air to circulate freely, it contributes to a safer and healthier work environment. Additionally, many manufacturers utilize recycled materials in the production of expanded metal grating, further reducing the ecological footprint.

Installation and maintenance are straightforward, adding to the allure of expanded metal grating for industrial applications. Most systems can be easily cut to size and arranged in configurations that best suit the specific layout of a facility. Regular maintenance typically involves simple cleaning, as the open design reduces the accumulation of debris, making it easy to ensure that the grating remains functional and safe over time.

In conclusion, expanded metal grating stands out as a practical and efficient solution for various industrial needs. Its combination of strength, safety, cost-effectiveness, versatility, and environmental benefits makes it an indispensable component in modern industrial design. Whether for flooring, walkways, or other applications, its unique properties cater to the demands of today’s dynamic work environments, ensuring safety and reliability in the processes that drive our industries forward.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.