1 月 . 15, 2025 09:09

Back to list

expanded mesh suppliers

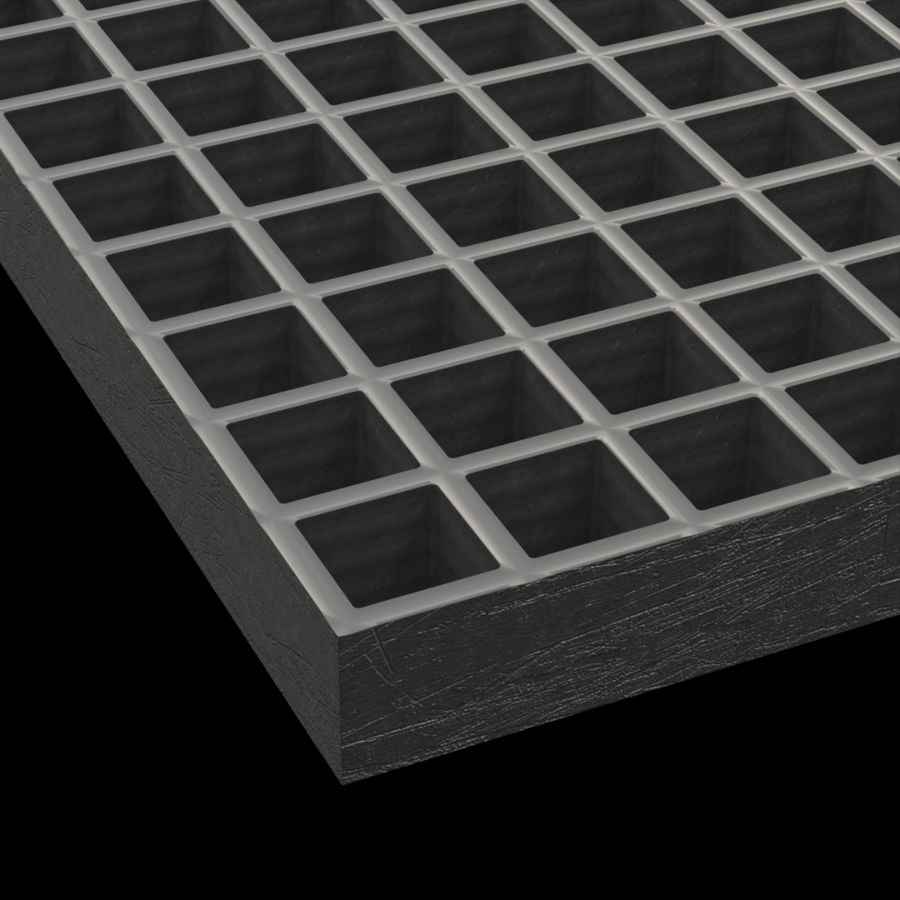

Finding the right expanded mesh suppliers can significantly influence the efficiency and success of your projects. As companies and industries continually seek robust materials for various applications, expanded mesh has surged in popularity due to its versatility and durability. Having worked closely with numerous suppliers and integrators over the years, I have gathered some insightful experiences that not only highlight expertise but also validate the authority and trustworthiness required when choosing the perfect supplier.

Moreover, authoritativeness and trustworthiness are reflected through accreditations and quality certifications. These endorsements serve as evidence that the supplier adheres to recognized standards and practices, such as ISO or ASTM standards. It reassures clients of the supplier's commitment to quality and reliability. Furthermore, a reputable supplier will have positive reviews and testimonials, possibly even displaying case studies that demonstrate successful projects where their expanded mesh played a crucial role. In addition to traditional credentials, look to see if a supplier is embracing innovation within their processes. Technological advancements such as CAD design capabilities or CNC machinery can enhance product precision and quality, ensuring clients receive the most modern solutions available in the market. Suppliers who invest in such technology underscore their commitment to maintaining a competitive edge and providing superior products. Finally, a trustworthy supplier establishes a transparent communication channel, offering comprehensive documentation that outlines product specifications, warranty information, and maintenance guidance. This transparency fosters a relationship of trust, as clients are kept informed and assured of the product's performance and the supplier's accountability. In conclusion, when seeking expanded mesh suppliers, rely on those who embody expertise, authoritativeness, and trustworthiness. Support your decision by evaluating their material knowledge, customizability options, industry experience, certifications, innovative capabilities, and transparency. This approach will not only enhance the likelihood of project success but also ensure that you are working with a reliable partner who is dedicated to meeting your needs with precision and proficiency.

Moreover, authoritativeness and trustworthiness are reflected through accreditations and quality certifications. These endorsements serve as evidence that the supplier adheres to recognized standards and practices, such as ISO or ASTM standards. It reassures clients of the supplier's commitment to quality and reliability. Furthermore, a reputable supplier will have positive reviews and testimonials, possibly even displaying case studies that demonstrate successful projects where their expanded mesh played a crucial role. In addition to traditional credentials, look to see if a supplier is embracing innovation within their processes. Technological advancements such as CAD design capabilities or CNC machinery can enhance product precision and quality, ensuring clients receive the most modern solutions available in the market. Suppliers who invest in such technology underscore their commitment to maintaining a competitive edge and providing superior products. Finally, a trustworthy supplier establishes a transparent communication channel, offering comprehensive documentation that outlines product specifications, warranty information, and maintenance guidance. This transparency fosters a relationship of trust, as clients are kept informed and assured of the product's performance and the supplier's accountability. In conclusion, when seeking expanded mesh suppliers, rely on those who embody expertise, authoritativeness, and trustworthiness. Support your decision by evaluating their material knowledge, customizability options, industry experience, certifications, innovative capabilities, and transparency. This approach will not only enhance the likelihood of project success but also ensure that you are working with a reliable partner who is dedicated to meeting your needs with precision and proficiency.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP