2 月 . 15, 2025 09:35

Back to list

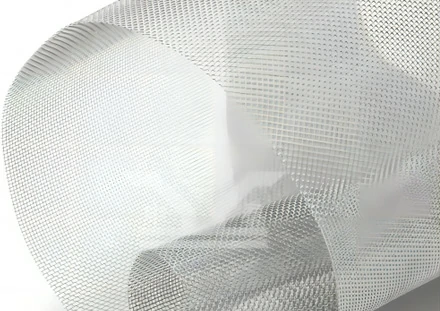

drain board waterproofing

Drain board waterproofing has become increasingly essential in the construction and landscaping industries, serving as a pivotal component in water management systems. Understanding the nuances of this technology can not only enhance the longevity of structures but also improve functionality. Here's a comprehensive examination of drain board waterproofing and its critical role in modern construction.

Trustworthiness in the drain board waterproofing industry is built on a foundation of proven performance and reliability. Manufacturers often support their products with extensive warranties and documented case studies that demonstrate reliability over time. It is crucial that industry professionals work with suppliers who offer transparent information about the expected lifespan of the product, maintenance requirements, and the specific conditions under which the product functions optimally. From a practical standpoint, the installation of drain board waterproofing systems should be performed by trained professionals who understand the intricacies of the system. Proper installation techniques ensure that the boards are adequately affixed to the surfaces and that the drainage channels remain unobstructed. Incorrect installation can lead to system failures, compromising the effectiveness of the waterproofing membrane and potentially leading to costly repairs. For product developers and engineers in the field, innovation continues to drive the evolution of drain board waterproofing. Advances in materials science have led to the development of more eco-friendly solutions that offer enhanced durability without sacrificing performance. These cutting-edge products provide an added layer of environmental responsibility, appealing to a growing segment of eco-conscious consumers seeking sustainable building practices. In summary, drain board waterproofing plays a critical role in the construction and longevity of any structure where water exposure is a concern. The dual functionality of these systems provides essential protection against water intrusion while facilitating ground drainage. By choosing products backed by authority and trust, adhering to strict standards, and employing experienced installers, stakeholders can ensure the integrity and durability of their buildings. As technology advances, the future of drain board waterproofing promises even greater innovation, performance, and sustainability, making it an integral aspect of modern construction endeavors.

Trustworthiness in the drain board waterproofing industry is built on a foundation of proven performance and reliability. Manufacturers often support their products with extensive warranties and documented case studies that demonstrate reliability over time. It is crucial that industry professionals work with suppliers who offer transparent information about the expected lifespan of the product, maintenance requirements, and the specific conditions under which the product functions optimally. From a practical standpoint, the installation of drain board waterproofing systems should be performed by trained professionals who understand the intricacies of the system. Proper installation techniques ensure that the boards are adequately affixed to the surfaces and that the drainage channels remain unobstructed. Incorrect installation can lead to system failures, compromising the effectiveness of the waterproofing membrane and potentially leading to costly repairs. For product developers and engineers in the field, innovation continues to drive the evolution of drain board waterproofing. Advances in materials science have led to the development of more eco-friendly solutions that offer enhanced durability without sacrificing performance. These cutting-edge products provide an added layer of environmental responsibility, appealing to a growing segment of eco-conscious consumers seeking sustainable building practices. In summary, drain board waterproofing plays a critical role in the construction and longevity of any structure where water exposure is a concern. The dual functionality of these systems provides essential protection against water intrusion while facilitating ground drainage. By choosing products backed by authority and trust, adhering to strict standards, and employing experienced installers, stakeholders can ensure the integrity and durability of their buildings. As technology advances, the future of drain board waterproofing promises even greater innovation, performance, and sustainability, making it an integral aspect of modern construction endeavors.

Next:

Latest news

-

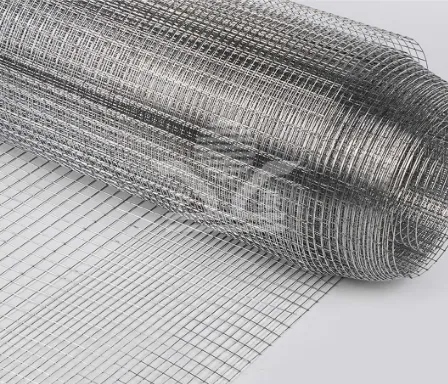

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP