2 月 . 10, 2025 17:58

Back to list

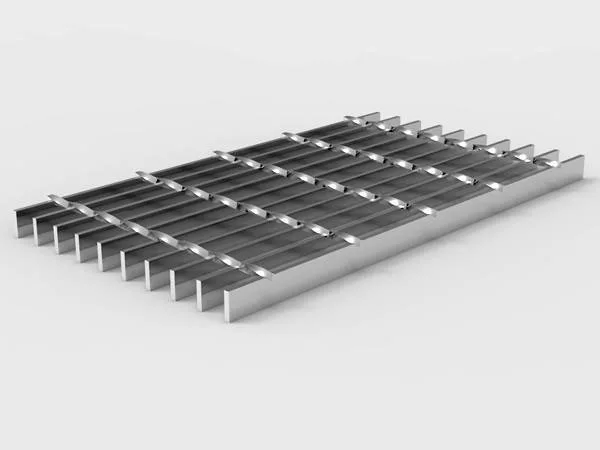

Stainless Steel Trench Drain Cover Gutter Grating

Custom perforated metal panels are revolutionizing the architectural and industrial design sectors, offering both functional and aesthetic benefits. These panels are meticulously designed with varied hole sizes, shapes, and patterns to meet specific client requirements. With decades of evolution, they have become a staple not only in creating striking building facades but also in various industrial applications. This article delves deep into the versatility, expertise, and reliability associated with custom perforated metal panels.

Trust in custom perforated metal panels is built through the reliability and consistency of the products delivered. Manufacturers emphasize stringent testing protocols that ensure each panel can endure environmental stressors and meet the demanding expectations of industrial use. From anti-corrosion treatments to resistance against wear and tear, every aspect is scrutinized to uphold the integrity and longevity of the product. The collaborative design process between the manufacturer and the client is crucial in achieving desired outcomes. Clients engage with design experts who provide insights and recommendations based on years of industry experience. This interaction not only helps in refining ideas but also ensures that the final product aligns with both aesthetic visions and operational requirements. Transparency in communication and commitment to client satisfaction reinforce the trustworthy reputation manufacturers have cultivated over the years. Another aspect that enhances the authoritative stature of custom perforated metal panels is their compliance with international quality standards. Certifications such as ISO and other regulatory benchmarks offer reassurance to clients about the product’s capability to perform as expected. Such certifications reflect the manufacturer's dedication to excellence and innovation, further building trust with their client base. In conclusion, custom perforated metal panels represent a marriage of innovation, design flexibility, and functionality. Their growing popularity in architectural and industrial domains can be attributed to their adaptability, aesthetic appeal, and performance reliability. Manufacturers who stand out in this field do so by demonstrating unmatched expertise and a commitment to high-quality craftsmanship. Whether enhancing the visual intrigue of a modern building or optimizing industrial processes, custom perforated metal panels continue to prove their worth as a crucial building material in contemporary design.

Trust in custom perforated metal panels is built through the reliability and consistency of the products delivered. Manufacturers emphasize stringent testing protocols that ensure each panel can endure environmental stressors and meet the demanding expectations of industrial use. From anti-corrosion treatments to resistance against wear and tear, every aspect is scrutinized to uphold the integrity and longevity of the product. The collaborative design process between the manufacturer and the client is crucial in achieving desired outcomes. Clients engage with design experts who provide insights and recommendations based on years of industry experience. This interaction not only helps in refining ideas but also ensures that the final product aligns with both aesthetic visions and operational requirements. Transparency in communication and commitment to client satisfaction reinforce the trustworthy reputation manufacturers have cultivated over the years. Another aspect that enhances the authoritative stature of custom perforated metal panels is their compliance with international quality standards. Certifications such as ISO and other regulatory benchmarks offer reassurance to clients about the product’s capability to perform as expected. Such certifications reflect the manufacturer's dedication to excellence and innovation, further building trust with their client base. In conclusion, custom perforated metal panels represent a marriage of innovation, design flexibility, and functionality. Their growing popularity in architectural and industrial domains can be attributed to their adaptability, aesthetic appeal, and performance reliability. Manufacturers who stand out in this field do so by demonstrating unmatched expertise and a commitment to high-quality craftsmanship. Whether enhancing the visual intrigue of a modern building or optimizing industrial processes, custom perforated metal panels continue to prove their worth as a crucial building material in contemporary design.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP