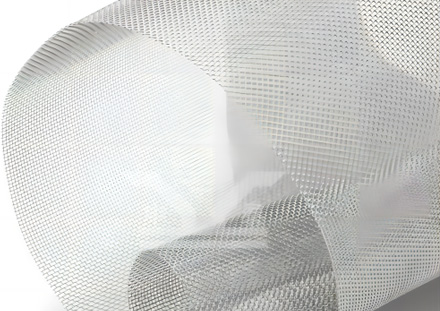

Custom Perforated Aluminum Sheets Versatility and Applications

Custom perforated aluminum sheets have become an essential material in various industries, thanks to their versatility, aesthetic appeal, and functional benefits. These sheets feature a series of holes or openings, which can be tailored to specific designs and requirements. This article will explore the advantages, manufacturing processes, and applications of custom perforated aluminum sheets.

Advantages of Perforated Aluminum Sheets

1. Lightweight and Durable Aluminum is known for its lightweight properties, making it easy to handle and install. Despite its low weight, it possesses considerable strength and durability, allowing it to withstand harsh environmental conditions such as rain, wind, and even snow.

2. Corrosion Resistance One of the most significant advantages of aluminum is its natural corrosion resistance. When exposed to moisture and air, aluminum forms a protective oxide layer that prevents further corrosion. This property is particularly beneficial in outdoor applications where longevity is key.

3. Aesthetic Appeal Custom perforated aluminum sheets can enhance the visual appeal of both commercial and residential spaces. The array of hole sizes, shapes, and patterns available allows for creative designs that can complement architectural elements and improve overall aesthetics.

4. Sound and Light Control The unique perforation patterns can help control acoustics and lighting in a space. Perforated sheets are often used in building facades to create a balance between natural light and shade while also minimizing noise pollution.

5. Sustainability Aluminum is a highly recyclable material, making it an environmentally friendly choice. Custom perforated aluminum sheets can be recycled at the end of their life cycle without losing quality, reducing landfill waste and promoting sustainability.

Manufacturing Processes

The manufacturing of custom perforated aluminum sheets involves several key steps

2. Design Development Clients often provide specifications regarding hole size, pattern, and sheet dimensions. Advanced design software can assist in creating precise designs that meet specific requirements.

custom perforated aluminum sheet

3. Perforation Techniques There are various methods to create perforations in aluminum sheets, including - Punching This technique uses a punch press to make holes in the material, allowing for precise sizes and shapes. - Laser Cutting Laser cutting offers high accuracy and the ability to produce complex patterns with minimal distortion to the sheet.

4. Finishing After perforation, sheets can undergo treatments such as anodizing, painting, or powder coating. These processes enhance corrosion resistance and provide additional aesthetic options.

5. Quality Control A final inspection ensures that the sheets meet quality standards and adhere to client specifications before they are packaged and shipped.

Applications

Custom perforated aluminum sheets are utilized across a myriad of industries, including

- Architectural Design Used as cladding, sunshades, or decorative screens, these sheets add a modern touch to buildings while providing functional benefits like ventilation and light control. - Interior Design In interiors, they can be employed in ceiling designs, wall panels, and room dividers, allowing for artistic expression while maintaining privacy and acoustics.

- Automotive Perforated aluminum is often used in grilles, engine covers, and other components due to its strength and lightweight nature.

- Industrial Applications Ventilation systems in factories or warehouses frequently use perforated aluminum sheets to facilitate airflow while preventing the entry of larger debris.

- Consumer Products From lightweight furniture to decorative items, the use of custom perforated aluminum sheets in consumer products is on the rise, thanks to their aesthetic and functional properties.

Conclusion

Custom perforated aluminum sheets stand out as a robust, versatile, and aesthetically pleasing choice for various applications. The combination of lightweight strength, corrosion resistance, and customizable designs makes them a preferred material in both architectural and industrial contexts. As industries continue to innovate and pursue sustainability, the demand for custom perforated aluminum sheets is expected to grow, solidifying their place as a vital component in modern materials engineering.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.