1 月 . 29, 2025 01:42

Back to list

cost of steel grating

Navigating the Cost of Steel Grating A Comprehensive Guide for Informed Purchasing

1. Lifecycle Consideration While initial costs of high-quality materials might be steeper, considering the long-term value is crucial. Stainless steel, with its extended lifespan and reduced maintenance, can be more economical over time compared to regular steel that may require premature replacement. 2. Bulk Purchasing Ordering in bulk can lead to discounts, as manufacturers often reduce prices per unit when larger quantities are involved. This approach is especially beneficial for large-scale projects. 3. Supplier Reliability Partnering with reputable suppliers ensures quality and consistency. Researching a supplier’s track record, certifications, and customer reviews can prevent future complications and unnecessary expenses. Professional Expertise Matters Consulting with experienced engineers or procurement specialists can enhance the purchasing process. Their insights ensure that the steel grating chosen meets both technical specifications and budgetary constraints. They can also provide invaluable advice on innovative materials and newer technologies that could offer superior performance or cost benefits. Navigating Future Trends The steel industry is not static. Emerging technologies in production techniques and materials might soon influence pricing structures. Keeping abreast of these trends can provide a competitive edge and facilitate long-term planning. For instance, innovations in alloy production may offer more cost-efficient alternatives without compromising on durability or quality. Building Trust Through Transparency Transparent communication with suppliers and stakeholders ensures trust and smooth project execution. Regular updates and comprehensive documentation from order to delivery can mitigate risks associated with miscommunication and ensure all parties are aligned. In conclusion, understanding the multifaceted nature of steel grating costs empowers buyers to make decisions that balance quality with budgetary needs. By considering not just the immediate expenses but also the long-term implications and benefits, purchasers can secure not only a cost-efficient solution but also a reliable and durable one that serves its intended purpose effectively.

1. Lifecycle Consideration While initial costs of high-quality materials might be steeper, considering the long-term value is crucial. Stainless steel, with its extended lifespan and reduced maintenance, can be more economical over time compared to regular steel that may require premature replacement. 2. Bulk Purchasing Ordering in bulk can lead to discounts, as manufacturers often reduce prices per unit when larger quantities are involved. This approach is especially beneficial for large-scale projects. 3. Supplier Reliability Partnering with reputable suppliers ensures quality and consistency. Researching a supplier’s track record, certifications, and customer reviews can prevent future complications and unnecessary expenses. Professional Expertise Matters Consulting with experienced engineers or procurement specialists can enhance the purchasing process. Their insights ensure that the steel grating chosen meets both technical specifications and budgetary constraints. They can also provide invaluable advice on innovative materials and newer technologies that could offer superior performance or cost benefits. Navigating Future Trends The steel industry is not static. Emerging technologies in production techniques and materials might soon influence pricing structures. Keeping abreast of these trends can provide a competitive edge and facilitate long-term planning. For instance, innovations in alloy production may offer more cost-efficient alternatives without compromising on durability or quality. Building Trust Through Transparency Transparent communication with suppliers and stakeholders ensures trust and smooth project execution. Regular updates and comprehensive documentation from order to delivery can mitigate risks associated with miscommunication and ensure all parties are aligned. In conclusion, understanding the multifaceted nature of steel grating costs empowers buyers to make decisions that balance quality with budgetary needs. By considering not just the immediate expenses but also the long-term implications and benefits, purchasers can secure not only a cost-efficient solution but also a reliable and durable one that serves its intended purpose effectively.

Next:

Latest news

-

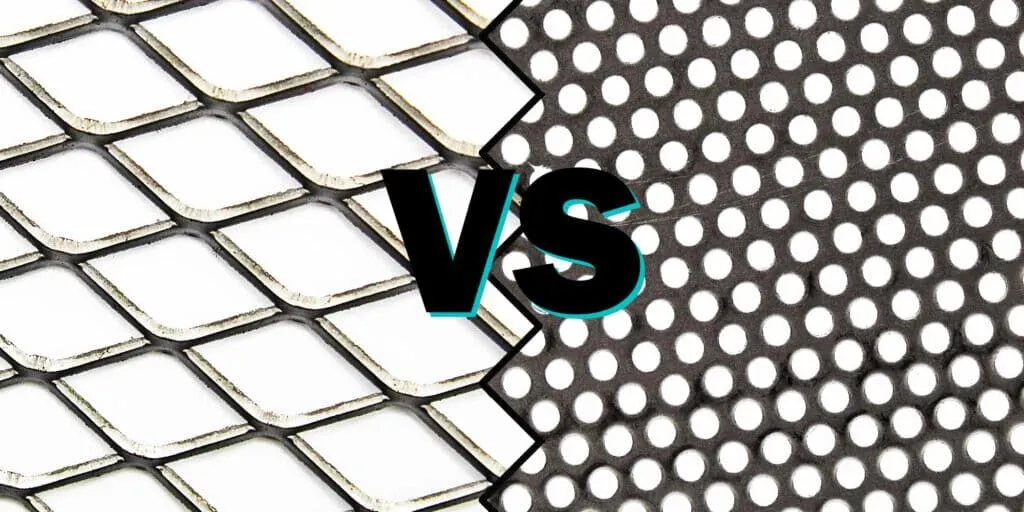

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP