Understanding Carbon Steel Perforated Sheets

Carbon steel perforated sheets are becoming increasingly popular in various industries due to their versatility, durability, and aesthetic appeal. These sheets are made from carbon steel, a strong and resilient material that offers an excellent balance of hardness and ductility. The distinctive feature of perforated sheets is their perforations, which are holes shaped in various patterns and sizes throughout the sheet. These perforations create a functional and ornamental design, enabling a wide range of applications.

One of the standout characteristics of carbon steel perforated sheets is their ability to provide both strength and lightweight benefits. This makes them ideal for applications where structural integrity is essential without adding unnecessary weight. From architectural designs to automotive applications, carbon steel perforated sheets can be found in numerous settings, enhancing both functionality and aesthetic appeal.

Applications

The applications of carbon steel perforated sheets are vast. In construction, they are commonly utilized in facades, sunshades, and railings, adding an element of design while allowing for ventilation and light control. Industrial settings often use these sheets in filtration systems, sound barriers, and safety guards, where their strength and durability are essential for maintaining safe operations.

In the furniture industry, perforated sheets are used to create contemporary designs in tables, chairs, and shelving, reflecting a modern aesthetic. Additionally, in the agricultural sector, these sheets can be employed in equipment and structures, providing necessary rigidity without being overly heavy.

Benefits

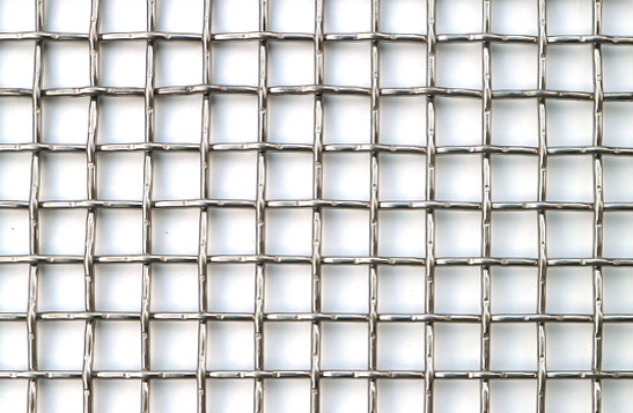

carbon steel perforated sheet

One of the primary benefits of carbon steel perforated sheets is their cost-effectiveness

. Carbon steel is generally less expensive than other metals like stainless steel or aluminum, making perforated sheets an economical choice for manufacturers and builders. Moreover, their recyclability adds another layer of sustainability, appealing to environmentally-conscious industries.Furthermore, the perforation patterns can be customized to fit specific needs. Whether it’s the size, shape, or spacing of the holes, manufacturers can tailor the sheets to meet unique project requirements. This customization allows for innovation in design while maintaining the load-bearing capabilities of the material.

Durability and Maintenance

When properly treated and maintained, carbon steel perforated sheets can exhibit excellent durability. They are resistant to mechanical wear and can endure harsh conditions, which is particularly advantageous in outdoor settings. However, because carbon steel is prone to rusting when exposed to moisture or corrosive elements, it is often coated with protective finishes to enhance its lifespan. Regular maintenance, such as cleaning and applying protective coatings, can help preserve the integrity of the material.

Conclusion

In conclusion, carbon steel perforated sheets offer a unique combination of strength, versatility, and aesthetic appeal, making them a popular choice across various industries. Their functional design, coupled with customizable options, makes them an excellent resource for architects, manufacturers, and designers alike. As industries continue to innovate, the use of carbon steel perforated sheets is likely to expand, further emphasizing their importance in modern applications.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.