1 月 . 31, 2025 05:46

Back to list

Black Welded Mesh Panels 16 X 16 X 1.4 X 1000mm X 25m 28.5 Kg Welded Wire Mesh

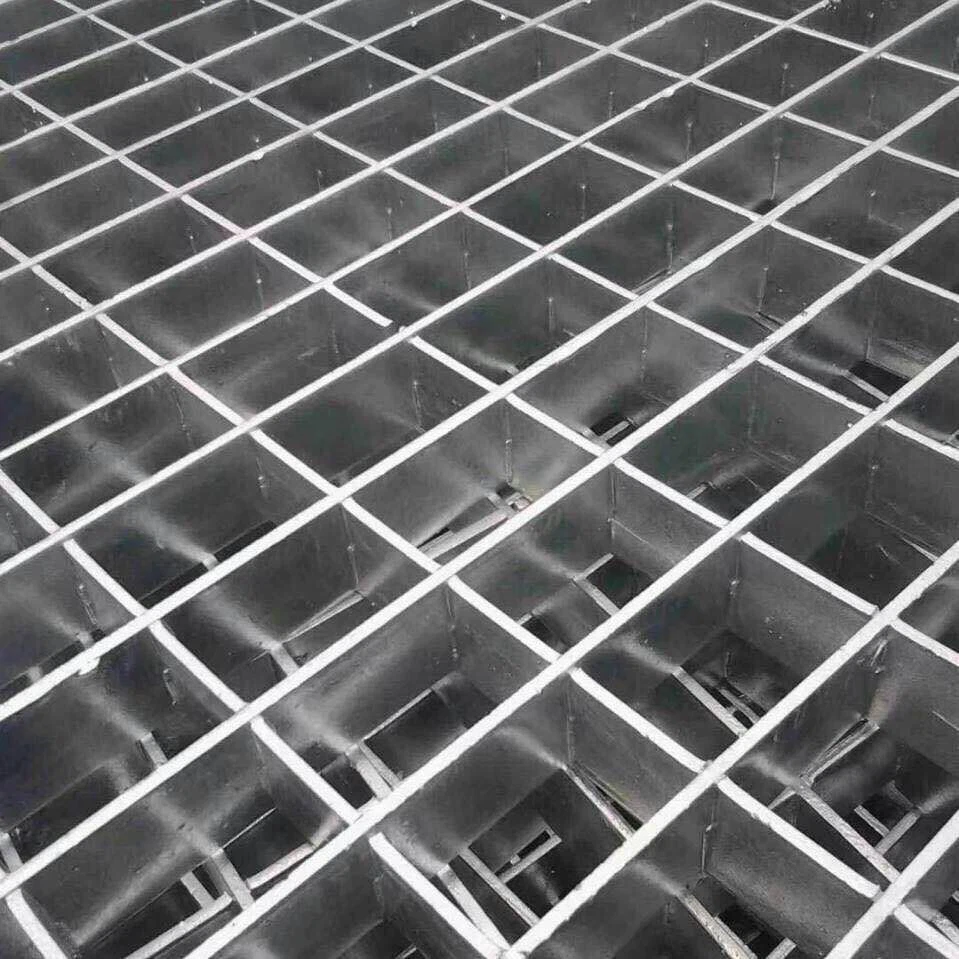

Bar grating treads have revolutionized the design and safety of walkways, staircases, and platforms in both industrial and commercial environments. The unique construction of bar grating treads consists of a series of bearing bars intersected at right angles by cross bars, creating an open, yet remarkably sturdy pattern. This design not only creates structural integrity but also facilitates effective drainage, minimizing the risk of accidents due to liquid accumulation.

The installation process of bar grating treads requires precise planning and execution. It begins with accurately measuring the area to ensure the grating fits perfectly. The installation typically involves welding, bolting, or clamping the grating to the supporting structure, each method providing unique advantages. Welding ensures permanent, solid joints suitable for industrial use. Bolted connections offer easy removal and replacement, ideal for temporary setups or areas requiring frequent maintenance. Clamping provides a balance between stability and flexibility, securing the grating without permanent modification to the support frame. Maintenance of bar grating treads, although minimal, is essential to extend their lifespan and maintain safety standards. Regular inspections should be conducted to check for structural integrity, ensuring no deformation or corrosion is present. Cleaning should be performed using appropriate methods that suit the material of the treads, such as pressure washing for steel and mild detergents for fiberglass. This not only prolongs the aesthetic value but also ensures optimal function and safety over time. Innovations in bar grating technology continue to enhance its application across diverse industries. Modern projects increasingly incorporate customized patterns that reflect creative designs, contributing to the visual appeal without compromising on strength or utility. As technology advances, bar grating treads continue to evolve, integrating smart features such as embedded sensors for monitoring load and environmental conditions, representing the future of intelligent infrastructure solutions. Trusting your grating needs to experienced manufacturers and suppliers is critical. Their expertise ensures access to high-quality materials certified to meet safety and industry standards. Companies benefiting from these innovations enjoy enhanced reliability, efficiency, and compliance, crucial for both regulatory purposes and operational excellence. In conclusion, bar grating treads represent a perfect synthesis of engineering prowess and material science. Whether it’s ensuring the safety of industrial workers or enhancing the architectural appeal of urban buildings, they are a cornerstone component. Understanding their unique benefits and appropriate applications is paramount, and professionals in this field stand ready to guide decision-makers to solutions that align perfectly with their operational goals.

The installation process of bar grating treads requires precise planning and execution. It begins with accurately measuring the area to ensure the grating fits perfectly. The installation typically involves welding, bolting, or clamping the grating to the supporting structure, each method providing unique advantages. Welding ensures permanent, solid joints suitable for industrial use. Bolted connections offer easy removal and replacement, ideal for temporary setups or areas requiring frequent maintenance. Clamping provides a balance between stability and flexibility, securing the grating without permanent modification to the support frame. Maintenance of bar grating treads, although minimal, is essential to extend their lifespan and maintain safety standards. Regular inspections should be conducted to check for structural integrity, ensuring no deformation or corrosion is present. Cleaning should be performed using appropriate methods that suit the material of the treads, such as pressure washing for steel and mild detergents for fiberglass. This not only prolongs the aesthetic value but also ensures optimal function and safety over time. Innovations in bar grating technology continue to enhance its application across diverse industries. Modern projects increasingly incorporate customized patterns that reflect creative designs, contributing to the visual appeal without compromising on strength or utility. As technology advances, bar grating treads continue to evolve, integrating smart features such as embedded sensors for monitoring load and environmental conditions, representing the future of intelligent infrastructure solutions. Trusting your grating needs to experienced manufacturers and suppliers is critical. Their expertise ensures access to high-quality materials certified to meet safety and industry standards. Companies benefiting from these innovations enjoy enhanced reliability, efficiency, and compliance, crucial for both regulatory purposes and operational excellence. In conclusion, bar grating treads represent a perfect synthesis of engineering prowess and material science. Whether it’s ensuring the safety of industrial workers or enhancing the architectural appeal of urban buildings, they are a cornerstone component. Understanding their unique benefits and appropriate applications is paramount, and professionals in this field stand ready to guide decision-makers to solutions that align perfectly with their operational goals.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP