Understanding Bar Grating Treads A Comprehensive Overview

Bar grating treads are an essential component in numerous industrial and commercial applications, providing safety, stability, and longevity to various structures. These treads, often made from steel, aluminum, or fiberglass, are designed to enhance traction and reduce the risk of slips and falls in environments where safety is paramount.

What Are Bar Grating Treads?

Bar grating treads are flat surfaces that consist of a series of parallel bars spaced apart with an appropriate gap. This design allows for water and debris to fall through while providing a stable walking surface. They are primarily used on stairs, walkways, and ramps, particularly in areas that are exposed to heavy foot traffic or where materials and equipment are moved frequently.

Types of Bar Grating Treads

There are several types of bar grating treads available, each with unique characteristics suited for specific applications

1. Steel Bar Grating Treads These are the most commonly used type, known for their strength and durability. They can support heavy loads, making them ideal for industrial settings, factories, and warehouses.

2. Aluminum Bar Grating Treads Aluminum provides a lightweight yet robust alternative to steel. It is highly resistant to corrosion, making it suitable for outdoor applications or environments with chemical exposure.

3. Fiberglass Bar Grating Treads For areas where safety is a concern due to possible electrical hazards, fiberglass grating is an excellent choice. It is non-conductive, lightweight, and resistant to corrosive materials, ideal for chemical plants and wastewater facilities.

Key Benefits of Bar Grating Treads

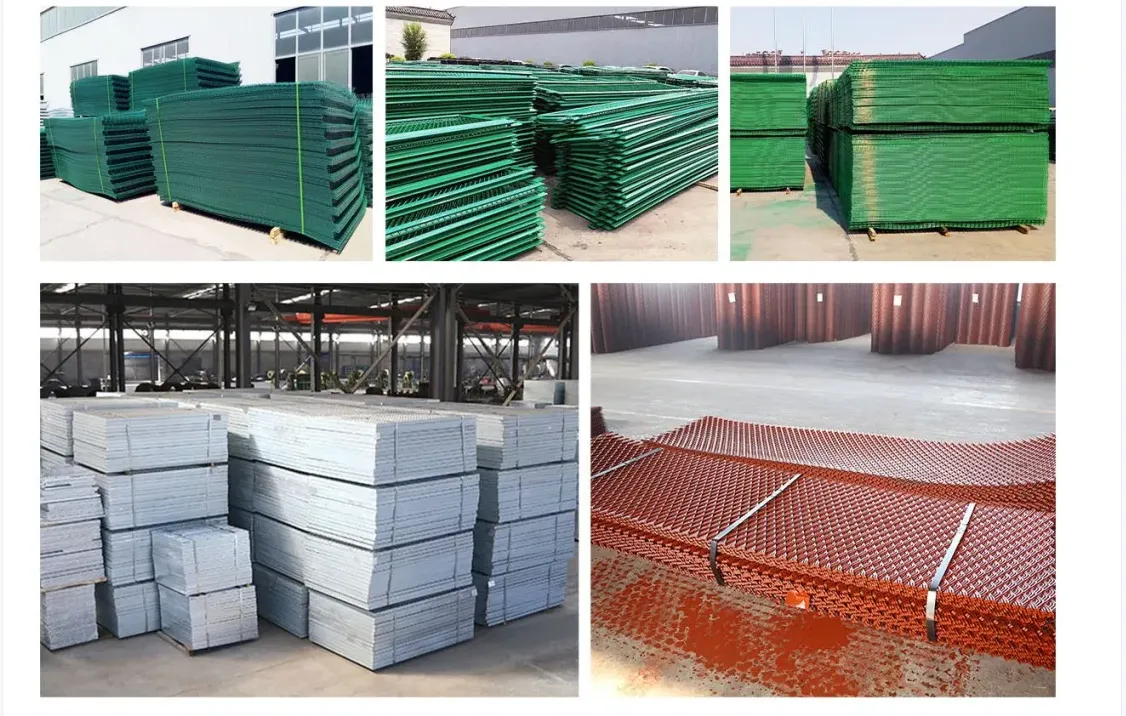

bar grating treads

1. Safety The open design of bar grating helps to prevent water accumulation and ice formation, significantly reducing slip and fall accidents. Various tread designs can enhance traction even in wet or greasy conditions.

2. Durability Bar grating treads are built to withstand heavy wear and tear. They can endure harsh environmental conditions, making them a long-lasting investment for any facility.

3. Customization Bar grating treads can be custom-designed to fit specific dimensions and load requirements. This versatility allows for tailored solutions that meet the unique needs of different projects.

4. Easy Maintenance Cleaning is straightforward, as debris often falls through the gaps. This feature helps maintain a clean and safe working environment with minimal effort.

Applications

Bar grating treads are widely used in various industries, including

- Manufacturing For loading docks, catwalks, and stairways. - Chemical Processing Where resistance to corrosive materials is essential. - Wastewater Treatment To ensure safety in areas prone to water exposure. - Power Plants For walkways and staircases that require high durability.

Conclusion

In summary, bar grating treads are a vital component in promoting safety and efficiency across various industries. With their array of materials, durability, and design capabilities, they provide practical solutions for both pedestrian and industrial applications. When considering options for treads, bar grating emerges as a reliable and innovative choice, ensuring environments are secure and functional for everyday use.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.