1 月 . 31, 2025 04:10

Back to list

bar grating stair tread

When selecting bar grating stair treads for your project, understanding the nuanced benefits and applications of this versatile product can provide an edge in both efficiency and safety. As a professional or homeowner tasked with enhancing structural integrity while ensuring top-tier performance, delving into the specifics of bar grating stair treads can be your pathway to success.

The safety benefits extend beyond basic functionality. Many designs include a nonslip nosing feature, enhancing grip and reducing the likelihood of accidents. This is particularly advantageous in facilities with high foot traffic or where particular caution is needed due to complex machinery operations. By reducing slip and fall incidents, these stair treads underscore a commitment to employee well-being and operational reliability. Experts who understand the impact of these products emphasize the importance of quality sourcing. Partnering with a reputable manufacturer guarantees a consistent standard of material and production excellence. Such partnerships often provide insight into the latest innovations and compliance with industry standards, a critical aspect of maintaining both safety and longevity in high-demand environments. Ultimately, prioritizing expertise in bar grating stair treads selection can transform how spaces are utilized. Through informed choices regarding materials, design, and manufacturer partnerships, projects not only meet regulatory requirements but also enhance overall functionality. The blend of robust design with strategic knowledge application ensures that each installation provides maximum efficiency and safety. For those seeking to ensure the utmost in safety and performance, the investment in carefully selected bar grating stair treads offers dividends in reduced maintenance costs, increased safety records, and a streamlined operational flow, underscoring their essential role in modern architecture and industrial design. By leveraging expertise in their selection and application, any project can achieve an elevated standard of excellence.

The safety benefits extend beyond basic functionality. Many designs include a nonslip nosing feature, enhancing grip and reducing the likelihood of accidents. This is particularly advantageous in facilities with high foot traffic or where particular caution is needed due to complex machinery operations. By reducing slip and fall incidents, these stair treads underscore a commitment to employee well-being and operational reliability. Experts who understand the impact of these products emphasize the importance of quality sourcing. Partnering with a reputable manufacturer guarantees a consistent standard of material and production excellence. Such partnerships often provide insight into the latest innovations and compliance with industry standards, a critical aspect of maintaining both safety and longevity in high-demand environments. Ultimately, prioritizing expertise in bar grating stair treads selection can transform how spaces are utilized. Through informed choices regarding materials, design, and manufacturer partnerships, projects not only meet regulatory requirements but also enhance overall functionality. The blend of robust design with strategic knowledge application ensures that each installation provides maximum efficiency and safety. For those seeking to ensure the utmost in safety and performance, the investment in carefully selected bar grating stair treads offers dividends in reduced maintenance costs, increased safety records, and a streamlined operational flow, underscoring their essential role in modern architecture and industrial design. By leveraging expertise in their selection and application, any project can achieve an elevated standard of excellence.

Next:

Latest news

-

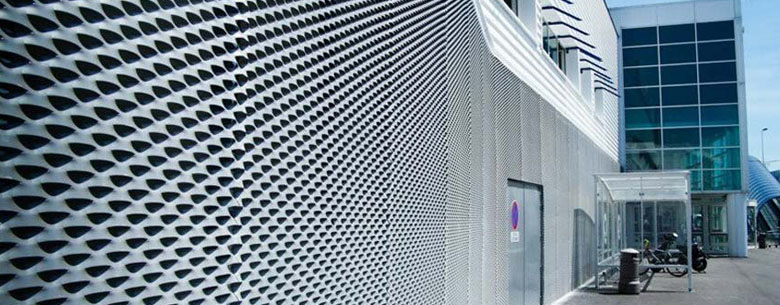

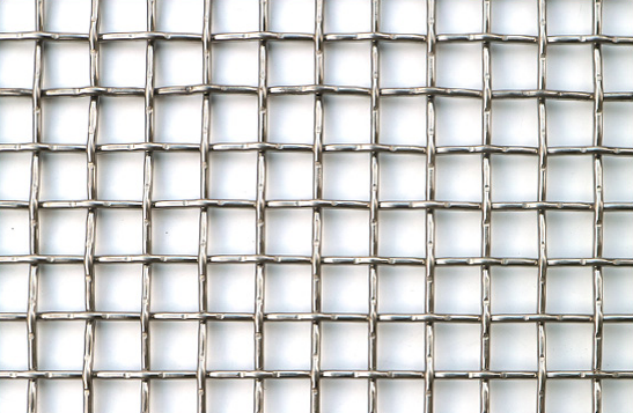

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP