1 月 . 28, 2025 05:16

Back to list

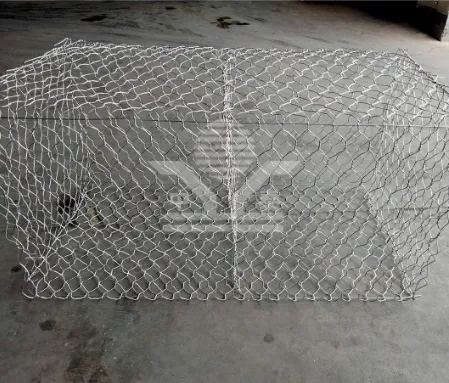

Australia Temporary Fence

Bar grating prices have increasingly become a focal point for businesses in industries ranging from construction to manufacturing. Understanding the factors that influence these costs can provide valuable insights and guide purchasing decisions. This consideration becomes especially important when managing budgets and ensuring that the materials align with safety and structural requirements.

Geographical location bears relevance to bar grating pricing, as proximity to manufacturing facilities can reduce transportation and shipping costs. Companies in regions with a high concentration of manufacturers may benefit from reduced logistical expenses. Conversely, businesses operating in remote areas may experience higher prices due to the increased complexity of delivering the product across long distances. Sustainability trends are increasingly influencing material choices and costs. More companies are choosing to invest in environmentally friendly materials and practices, which often come at a premium. However, this investment often translates to long-term savings through reduced maintenance and compliance with environmental regulations, which can offset initial costs. The purchasing process also has implications for bar grating prices. Engaging in bulk purchases often yields discounts, as sellers provide incentives for larger orders. Also, establishing long-term partnerships with suppliers can lock in prices and offer benefits like prioritized service and tailored payment terms, contributing to overall cost-effectiveness. In conclusion, bar grating prices are influenced by a complex interplay of material choices, manufacturing strategies, market dynamics, geographical factors, sustainability trends, and purchasing methods. Businesses can optimize their investments by comprehensively understanding these factors and strategically approaching their sourcing processes. Ultimately, smart decision-making not only secures the best possible pricing but also ensures alignment with performance requirements and sustainable practices.

Geographical location bears relevance to bar grating pricing, as proximity to manufacturing facilities can reduce transportation and shipping costs. Companies in regions with a high concentration of manufacturers may benefit from reduced logistical expenses. Conversely, businesses operating in remote areas may experience higher prices due to the increased complexity of delivering the product across long distances. Sustainability trends are increasingly influencing material choices and costs. More companies are choosing to invest in environmentally friendly materials and practices, which often come at a premium. However, this investment often translates to long-term savings through reduced maintenance and compliance with environmental regulations, which can offset initial costs. The purchasing process also has implications for bar grating prices. Engaging in bulk purchases often yields discounts, as sellers provide incentives for larger orders. Also, establishing long-term partnerships with suppliers can lock in prices and offer benefits like prioritized service and tailored payment terms, contributing to overall cost-effectiveness. In conclusion, bar grating prices are influenced by a complex interplay of material choices, manufacturing strategies, market dynamics, geographical factors, sustainability trends, and purchasing methods. Businesses can optimize their investments by comprehensively understanding these factors and strategically approaching their sourcing processes. Ultimately, smart decision-making not only secures the best possible pricing but also ensures alignment with performance requirements and sustainable practices.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP