1 月 . 25, 2025 20:18

Back to list

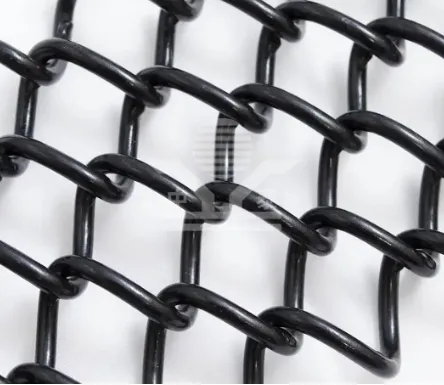

bar grating panels

Bar grating panels are essential components in a wide variety of industrial, commercial, and even residential applications due to their strength, versatility, and functionality. With decades of usage across numerous sectors, these grating systems have proven indispensable, primarily for flooring, walkways, and ventilation. One of the key parameters when considering bar grating panels for a given project is understanding their construction and material choices, which directly influence the performance and longevity of the grating.

A crucial consideration for bar grating panels is their load-resisting capacity. This involves understanding the distinction between uniform and concentrated loads, and ensuring that the selected grating can withstand the maximum anticipated load in its intended application. For safety and longevity, it is imperative to consult with grating manufacturers or structural engineers to verify that the grating specifications align with the structural needs and safety regulations of your project. Another aspect is the ease of installation and maintenance which can significantly impact both upfront costs and long-term operational expenses. Panels that are pre-cut and fitted to specific dimensions can facilitate straightforward installation, reducing labor costs and installation time. Maintenance often involves periodic cleaning and inspections, particularly in environments prone to debris accumulation or corrosive exposure. Innovative advancements in the industry have also led to the development of advanced coatings and specialty finishes that enhance safety and aesthetic appeal. Anti-slip coatings, for instance, are becoming increasingly vital in environments exposed to moisture or oils which may present slipping hazards. These enhancements further solidify the role of bar grating panels as a reliable and versatile solution in various settings. When choosing bar grating panels, it is paramount to engage with reputable and experienced manufacturers, ensuring access to quality materials, expert guidance, and adherence to industry standards. This engagement ensures that your selected bar grating panels will not only meet but exceed expectations in performance, safety, and durability, thereby contributing to the overall success of the project.

A crucial consideration for bar grating panels is their load-resisting capacity. This involves understanding the distinction between uniform and concentrated loads, and ensuring that the selected grating can withstand the maximum anticipated load in its intended application. For safety and longevity, it is imperative to consult with grating manufacturers or structural engineers to verify that the grating specifications align with the structural needs and safety regulations of your project. Another aspect is the ease of installation and maintenance which can significantly impact both upfront costs and long-term operational expenses. Panels that are pre-cut and fitted to specific dimensions can facilitate straightforward installation, reducing labor costs and installation time. Maintenance often involves periodic cleaning and inspections, particularly in environments prone to debris accumulation or corrosive exposure. Innovative advancements in the industry have also led to the development of advanced coatings and specialty finishes that enhance safety and aesthetic appeal. Anti-slip coatings, for instance, are becoming increasingly vital in environments exposed to moisture or oils which may present slipping hazards. These enhancements further solidify the role of bar grating panels as a reliable and versatile solution in various settings. When choosing bar grating panels, it is paramount to engage with reputable and experienced manufacturers, ensuring access to quality materials, expert guidance, and adherence to industry standards. This engagement ensures that your selected bar grating panels will not only meet but exceed expectations in performance, safety, and durability, thereby contributing to the overall success of the project.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP