2 月 . 13, 2025 11:10

Back to list

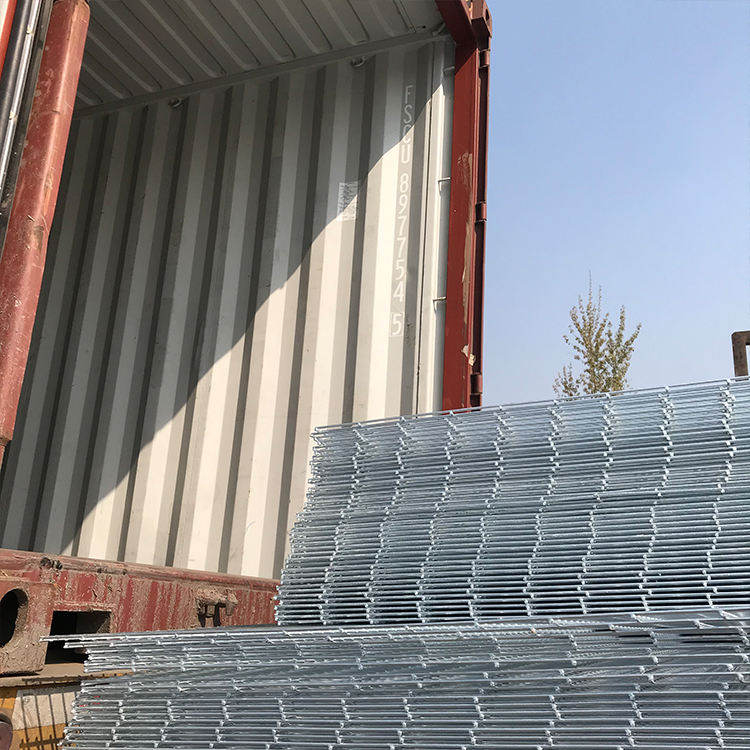

aluminum perforated metal screen sheet

Aluminum perforated metal screen sheets have been gaining substantial attention for their versatile applications ranging from architectural designs to industrial machinery. This guide delves into the nuances of these sheets, spotlighting their unique advantages, uses, and the factors making them indispensable in various industries.

When considering industrial applications, these sheets are remarkable for use as filters or vents. Their ability to allow air or liquid to pass through while blocking larger particles suits them perfectly for industrial filtration systems. Furthermore, the ease of maintenance and cleaning makes them a favorite for factories where hygiene and operational efficiency are top priorities. An often-overlooked benefit of aluminum perforated metal screens is their role in enhancing privacy and security without sacrificing aesthetics. When used in the construction of partitions or enclosures, they offer a visually appealing layer of privacy while maintaining the openness and transparency needed in modern spaces. The degree of privacy can easily be customized by adjusting the size and density of the perforations. The journey towards selecting the right aluminum perforated metal screen sheet involves several critical considerations. The choice of perforation pattern, hole size, and sheet thickness must align with the functional requirements and aesthetic goals of the specific project. This decision-making process is enhanced by engaging with an expert supplier who is not only experienced in manufacturing high-quality perforated sheets but also attuned to the latest trends and demands of various industry sectors. In addition, the installation process for these sheets must be handled with precision to maximize their performance and lifespan. Professionals equipped with the knowledge of appropriate fastening techniques and tools are essential to ensure that the sheets do not face unnecessary stress or deformation during installation. In conclusion, aluminum perforated metal screen sheets encapsulate a blend of functionality, sustainability, and aesthetic appeal unmatched by many other construction materials. Their growing popularity across various industries is a testament to their unique properties and adaptability. As we continue to seek out materials that promote energy efficiency and sustainability, aluminum perforated screens are poised to remain at the forefront of innovative design and utility. Engaging with experts who have extensive experience in this field ensures that you harness the full potential of these versatile sheets, paving the way for groundbreaking solutions in both existing and emerging applications.

When considering industrial applications, these sheets are remarkable for use as filters or vents. Their ability to allow air or liquid to pass through while blocking larger particles suits them perfectly for industrial filtration systems. Furthermore, the ease of maintenance and cleaning makes them a favorite for factories where hygiene and operational efficiency are top priorities. An often-overlooked benefit of aluminum perforated metal screens is their role in enhancing privacy and security without sacrificing aesthetics. When used in the construction of partitions or enclosures, they offer a visually appealing layer of privacy while maintaining the openness and transparency needed in modern spaces. The degree of privacy can easily be customized by adjusting the size and density of the perforations. The journey towards selecting the right aluminum perforated metal screen sheet involves several critical considerations. The choice of perforation pattern, hole size, and sheet thickness must align with the functional requirements and aesthetic goals of the specific project. This decision-making process is enhanced by engaging with an expert supplier who is not only experienced in manufacturing high-quality perforated sheets but also attuned to the latest trends and demands of various industry sectors. In addition, the installation process for these sheets must be handled with precision to maximize their performance and lifespan. Professionals equipped with the knowledge of appropriate fastening techniques and tools are essential to ensure that the sheets do not face unnecessary stress or deformation during installation. In conclusion, aluminum perforated metal screen sheets encapsulate a blend of functionality, sustainability, and aesthetic appeal unmatched by many other construction materials. Their growing popularity across various industries is a testament to their unique properties and adaptability. As we continue to seek out materials that promote energy efficiency and sustainability, aluminum perforated screens are poised to remain at the forefront of innovative design and utility. Engaging with experts who have extensive experience in this field ensures that you harness the full potential of these versatile sheets, paving the way for groundbreaking solutions in both existing and emerging applications.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP