Understanding Aluminium Perforated Metal Sheets Versatility and Applications

Aluminium perforated metal sheets have gained immense popularity in various industries due to their unique combination of light weight, durability, and aesthetic appeal. These sheets are crafted from high-quality aluminium and feature a series of holes punched into them, allowing for a range of functionalities and benefits that set them apart from other materials.

What is Aluminium Perforated Metal Sheet?

An aluminium perforated metal sheet is a flat piece of metal that has been systematically pierced with holes to create a distinctive pattern. The perforation process can produce different hole shapes, sizes, and patterns depending on the intended application. The standard thickness of these sheets varies, typically ranging from 0.25 mm to 6 mm, making them suitable for a wide array of applications from light structural elements to robust industrial uses.

Advantages of Aluminium Perforated Metal Sheets

1. Lightweight and Durable Aluminium is known for its excellent strength-to-weight ratio. This characteristic makes aluminium perforated sheets easy to handle and install while still offering substantial strength and corrosion resistance.

2. Aesthetic Appeal The ability to customize hole patterns makes aluminium perforated sheets visually appealing. They can be used in architectural applications to create striking facades, decorative partitions, or ceiling designs with unique light diffusion effects.

3. Ventilation and Filtration The holes in the sheets allow for effective airflow and light penetration, making them ideal for use in applications requiring ventilation, such as in HVAC systems, as well as filtration in industrial processes.

4. Sound Absorption Perforated sheets can also serve acoustic purposes. The holes can help in sound absorption, making them a great choice for soundproofing applications in auditoriums, theatres, or industrial facilities.

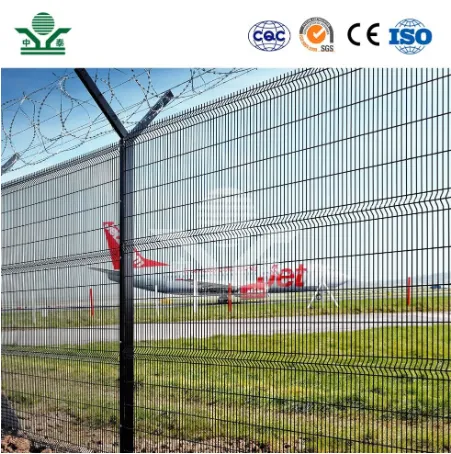

aluminium perforated metal sheet

5. Versatile Uses Aluminium perforated metal sheets are utilized in a wide range of sectors including architecture, construction, automotive, food processing, and agriculture. They are used for everything from signage and decoration to grilles, shields, and protective covers.

Applications of Aluminium Perforated Metal Sheets

1. Architectural Design In contemporary architecture, perforated metal sheets are deployed to create facades that not only enhance the building's aesthetic appeal but also provide sun shading and reduce energy costs by minimizing heat gain.

2. Industrial Uses In industrial settings, aluminium perforated sheets can be found in machinery guards, safety screens, and hoppers, where they protect workers while allowing for visibility and airflow.

3. Retail and Commercial Spaces These sheets are increasingly used in retail environments to create striking displays and fixtures. The ability to backlight perforated panels also adds an attractive dimension to product showcases.

4. Transportation In automotive and aerospace industries, aluminium perforated metal sheets are used for lightweight fixtures and components that require structural integrity without adding excessive weight.

5. Environmental Applications In waste management and environmental control, perforated sheets are used in composting bins and drainage covers, facilitating moisture control and air flow critical to decomposition processes.

Conclusion

The versatility and various advantages of aluminium perforated metal sheets make them an invaluable resource across multiple industries. Whether utilized for aesthetic purposes in architecture or functional applications in manufacturing and transport, these sheets provide an innovative solution that combines form and function. As technology advances, the potential for new applications and designs continues to grow, ensuring that aluminium perforated sheets will remain an essential element in industrial design and architecture for years to come. Their unique blend of durability, weight efficiency, and aesthetic flexibility undoubtedly underscores their relevance in the modern marketplace.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.