2 月 . 13, 2025 13:07

Back to list

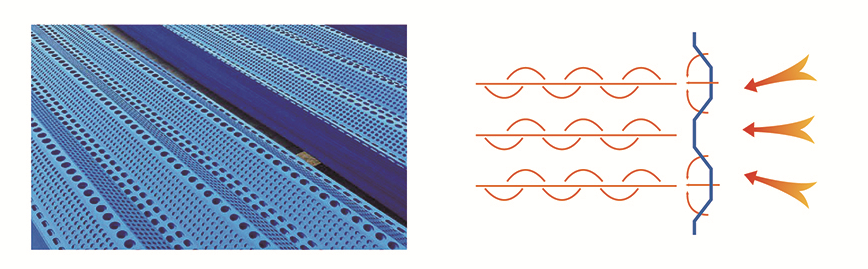

aluminium perforated metal sheet

Aluminium perforated metal sheets have emerged as an essential material in various industrial and architectural applications. Known for their lightweight, durability, and versatility, these sheets are an ideal choice for projects that require a perfect blend of aesthetic appeal and functionality.

Authoritativeness in the use of aluminium perforated metal sheets is evident from their widespread adoption in critical projects worldwide. Renowned architects and engineers specify these sheets for iconic buildings and structures, leveraging their visual appeal and structural benefits. The material’s contribution to sustainability has positioned it as a top choice for eco-friendly designs, with its ability to improve energy efficiency by reducing heat and glare when used in external facades or as sun shading devices. The trustworthiness of aluminium perforated sheets is reinforced by their resilience in a variety of environmental conditions. Aluminium naturally possesses anti-corrosive properties, which make it suitable for both indoor and outdoor applications without the risk of rust or degradation over time. Additionally, the sheets respond excellently to finishes such as powder coating and anodizing, which further enhance their resistance to environmental challenges and contribute to their longevity. This reliability reassures buyers that their investments in aluminium perforated metal sheets will not only meet but exceed expectations in terms of performance and lifespan. In conclusion, aluminium perforated metal sheets offer a unique combination of beauty, flexibility, and durability, making them an invaluable resource in the design and construction industries. Their role in enhancing aesthetic appeal while delivering on performance metrics such as weight management and atmospheric control underscores their growing importance in modern architectural and industrial applications. For those seeking a material that embodies both form and function, aluminium perforated sheets represent an authoritative and trustworthy choice.

Authoritativeness in the use of aluminium perforated metal sheets is evident from their widespread adoption in critical projects worldwide. Renowned architects and engineers specify these sheets for iconic buildings and structures, leveraging their visual appeal and structural benefits. The material’s contribution to sustainability has positioned it as a top choice for eco-friendly designs, with its ability to improve energy efficiency by reducing heat and glare when used in external facades or as sun shading devices. The trustworthiness of aluminium perforated sheets is reinforced by their resilience in a variety of environmental conditions. Aluminium naturally possesses anti-corrosive properties, which make it suitable for both indoor and outdoor applications without the risk of rust or degradation over time. Additionally, the sheets respond excellently to finishes such as powder coating and anodizing, which further enhance their resistance to environmental challenges and contribute to their longevity. This reliability reassures buyers that their investments in aluminium perforated metal sheets will not only meet but exceed expectations in terms of performance and lifespan. In conclusion, aluminium perforated metal sheets offer a unique combination of beauty, flexibility, and durability, making them an invaluable resource in the design and construction industries. Their role in enhancing aesthetic appeal while delivering on performance metrics such as weight management and atmospheric control underscores their growing importance in modern architectural and industrial applications. For those seeking a material that embodies both form and function, aluminium perforated sheets represent an authoritative and trustworthy choice.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP