Understanding 3mm Perforated Sheets Versatility and Applications

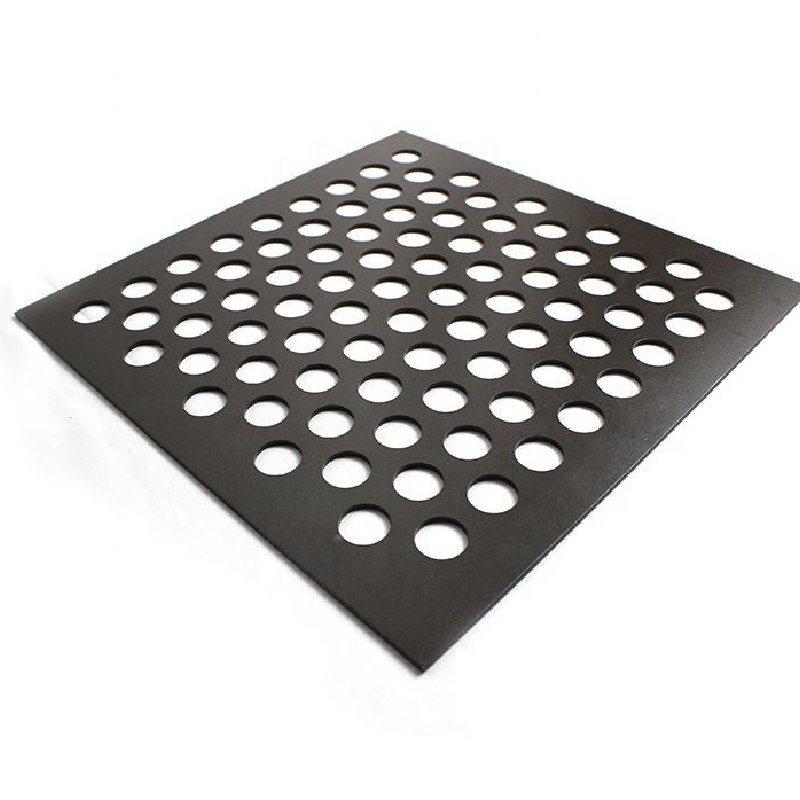

Perforated sheets are an essential component in various industries, known for their multifunctional properties and diverse applications. Among them, the 3mm perforated sheet stands out due to its balanced strength, durability, and aesthetic appeal. Typically made from materials like steel, aluminum, or plastic, these sheets feature a pattern of holes that are uniformly distributed across their surface.

One of the primary advantages of 3mm perforated sheets is their ability to offer both structural integrity and flexibility

. The 3mm thickness provides adequate support for many applications, making it suitable for use in construction, architecture, and engineering. This thickness ensures that the sheet can withstand environmental stresses while still being lightweight enough for easy handling and installation.In architectural applications, 3mm perforated sheets are frequently utilized for facades and interior design elements. They offer an eye-catching aesthetic, allowing light and air to filter through while providing privacy and shade. Designers often use these sheets to create striking visual patterns, enhancing the overall look of a building without compromising functionality. Additionally, their ability to manage acoustic properties makes them ideal for use in auditoriums and concert halls, where sound quality is crucial.

3mm perforated sheet

Industrial applications also benefit from 3mm perforated sheets. In the manufacturing sector, these sheets serve as filters, screens, or protective barriers. The holes in the perforated sheet can be customized in size and shape to meet specific requirements, allowing for versatile use in separating materials or controlling airflow in ventilation systems. In the food and pharmaceutical industries, 3mm perforated sheets are essential for ensuring hygiene and safety during production processes.

Another important aspect of perforated sheets is their ease of maintenance. The materials used are often resistant to corrosion and other environmental factors, meaning they can maintain their functionality and appearance over time with minimal upkeep. This longevity makes them a cost-effective solution in the long run, as businesses can reduce replacement frequency and maintenance costs.

In summary, 3mm perforated sheets serve various roles across multiple sectors. Their combination of strength, design flexibility, and practicality makes them an invaluable resource in both aesthetic and functional applications. Whether in architecture or manufacturing, the versatility of 3mm perforated sheets continues to make them a popular choice, proving that innovative design and engineering can go hand in hand.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.