2 月 . 14, 2025 07:00

Back to list

316 stainless steel perforated sheet

The world of metal fabrication is vast and diverse, yet specific materials stand out due to their unique properties and wide range of applications. One such material is the 316 stainless steel perforated sheet—a marvel of engineering that combines durability, versatility, and aesthetic appeal, making it indispensable in numerous sectors.

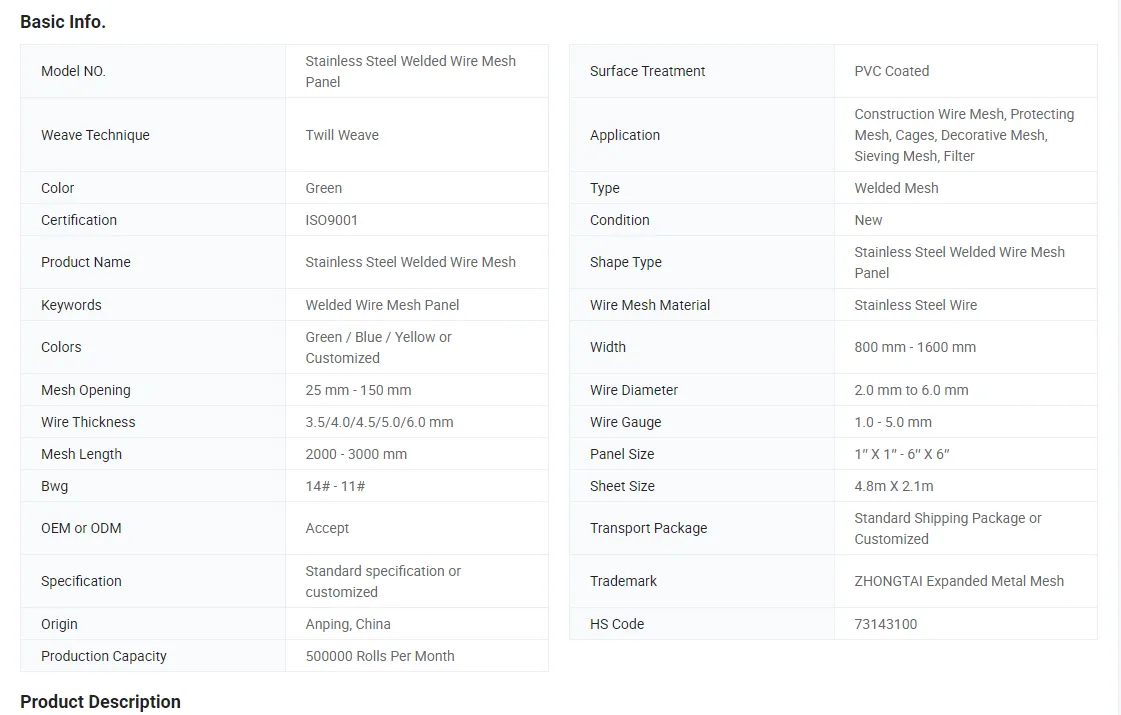

Trust in 316 stainless steel perforated sheets is further bolstered by rigorous quality standards and industry certifications. Many suppliers adhere to ISO guidelines and ASTM specifications, ensuring products meet stringent criteria for strength, durability, and uniformity. This authoritative consensus reassures clients across industries of the material's reliability and long-term value. It is through real-world experiences and customer testimonials that the advantages of 316 stainless steel perforated sheets come to life. In the realm of HVAC systems, they function as critical components in air filtration and diffusion applications due to their resistance to rust and corrosion when exposed to moist airflows. In the food processing industry, their easy-to-clean surfaces and compliance with sanitary regulations make them an ideal choice for equipment and surfaces that come into contact with consumables. The customizable aspect of 316 stainless steel perforated sheets cannot be overstated. With advancements in technology, manufacturers offer bespoke solutions with varied hole sizes, patterns, and sheet thicknesses. This flexibility allows designers to create bespoke solutions tailored to specific project requirements, from small-scale consumer products to large industrial installations. In conclusion, 316 stainless steel perforated sheets are a testament to the blend of evolved materials science and expert craftsmanship. Their unmatched corrosion resistance, aesthetic versatility, and structural integrity cater to an array of applications that demand both function and form. Whether in architecture, industry, or product design, these sheets serve as a benchmark of quality and innovation. Through ongoing innovation and adherence to stringent standards, 316 stainless steel perforated sheets continue to build trust and exemplify the pinnacle of what modern material science can achieve.

Trust in 316 stainless steel perforated sheets is further bolstered by rigorous quality standards and industry certifications. Many suppliers adhere to ISO guidelines and ASTM specifications, ensuring products meet stringent criteria for strength, durability, and uniformity. This authoritative consensus reassures clients across industries of the material's reliability and long-term value. It is through real-world experiences and customer testimonials that the advantages of 316 stainless steel perforated sheets come to life. In the realm of HVAC systems, they function as critical components in air filtration and diffusion applications due to their resistance to rust and corrosion when exposed to moist airflows. In the food processing industry, their easy-to-clean surfaces and compliance with sanitary regulations make them an ideal choice for equipment and surfaces that come into contact with consumables. The customizable aspect of 316 stainless steel perforated sheets cannot be overstated. With advancements in technology, manufacturers offer bespoke solutions with varied hole sizes, patterns, and sheet thicknesses. This flexibility allows designers to create bespoke solutions tailored to specific project requirements, from small-scale consumer products to large industrial installations. In conclusion, 316 stainless steel perforated sheets are a testament to the blend of evolved materials science and expert craftsmanship. Their unmatched corrosion resistance, aesthetic versatility, and structural integrity cater to an array of applications that demand both function and form. Whether in architecture, industry, or product design, these sheets serve as a benchmark of quality and innovation. Through ongoing innovation and adherence to stringent standards, 316 stainless steel perforated sheets continue to build trust and exemplify the pinnacle of what modern material science can achieve.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP