2 月 . 14, 2025 08:15

Back to list

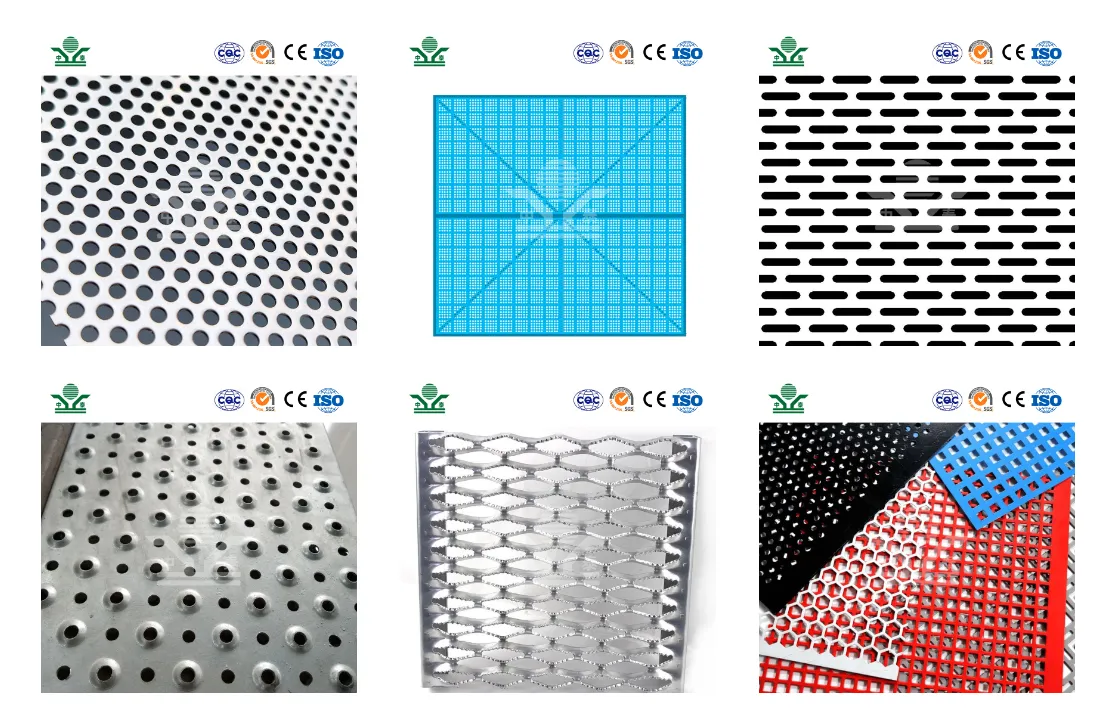

3 16 perforated steel sheet

Perforated steel sheets, specifically the 3/16 inch variety, have become a cornerstone in various industries, offering a blend of durability, versatility, and aesthetic appeal. These sheets, characterized by their precise and uniform perforations, have found their way into both industrial and architectural applications. With a focus on Experience, Expertise, Authoritativeness, and Trustworthiness, let's delve into the comprehensive qualities and applications of 3/16 perforated steel sheets.

Industrial applications are equally far-reaching. Perforated steel sheets are critical in creating filtering devices, eliminating unwanted debris from materials such as water, air, or various industrial fluids. The 3/16 thickness offers a balance between structural integrity and the ability to effectively manage particulates, making it an optimal choice for many filtration systems. Furthermore, the acoustic properties of perforated steel sheets make them ideal for noise control solutions. When engineered with the appropriate pattern and backed by sound-absorbing materials, they effectively reduce noise levels in busy environments such as manufacturing floors or public spaces. Sustainability is a growing concern for industries across the globe, and perforated steel sheets contribute positively to this trend. They are recyclable, and their durability ensures a long life span, reducing the need for frequent replacements. The use of steel from responsible sources adds another layer of environmental consciousness, aligning with green building certifications and eco-friendly construction practices. Maintenance of these steel sheets is straightforward. Regular cleaning to prevent dirt buildup ensures their appearance and functionality remain intact. The protective coatings available for these sheets enhance their natural resistance to corrosion, extending their life even in demanding environments. Ultimately, 3/16 perforated steel sheets represent a fusion of artistry and function, offering users the ability to realize their vision while meeting practical requirements. Their multifaceted applications affirm their place as a trusted material in both traditional and innovative uses. As industries continue to evolve, the demand for materials that blend experience, expertise, authoritativeness, and trustworthiness remains as strong as ever, with perforated steel sheets at the forefront of this dynamic landscape.

Industrial applications are equally far-reaching. Perforated steel sheets are critical in creating filtering devices, eliminating unwanted debris from materials such as water, air, or various industrial fluids. The 3/16 thickness offers a balance between structural integrity and the ability to effectively manage particulates, making it an optimal choice for many filtration systems. Furthermore, the acoustic properties of perforated steel sheets make them ideal for noise control solutions. When engineered with the appropriate pattern and backed by sound-absorbing materials, they effectively reduce noise levels in busy environments such as manufacturing floors or public spaces. Sustainability is a growing concern for industries across the globe, and perforated steel sheets contribute positively to this trend. They are recyclable, and their durability ensures a long life span, reducing the need for frequent replacements. The use of steel from responsible sources adds another layer of environmental consciousness, aligning with green building certifications and eco-friendly construction practices. Maintenance of these steel sheets is straightforward. Regular cleaning to prevent dirt buildup ensures their appearance and functionality remain intact. The protective coatings available for these sheets enhance their natural resistance to corrosion, extending their life even in demanding environments. Ultimately, 3/16 perforated steel sheets represent a fusion of artistry and function, offering users the ability to realize their vision while meeting practical requirements. Their multifaceted applications affirm their place as a trusted material in both traditional and innovative uses. As industries continue to evolve, the demand for materials that blend experience, expertise, authoritativeness, and trustworthiness remains as strong as ever, with perforated steel sheets at the forefront of this dynamic landscape.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP