1 月 . 23, 2025 01:41

Back to list

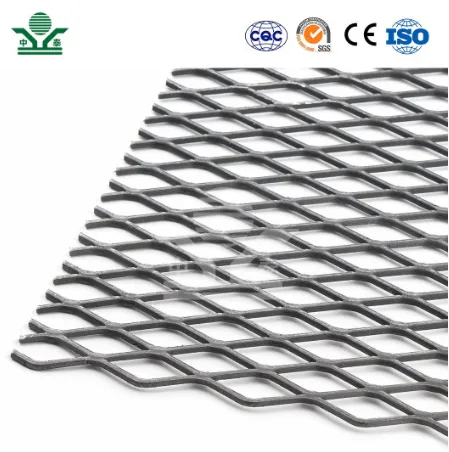

1 steel grating

Steel grating has become an indispensable component in various industrial applications, celebrated for its combination of strength, durability, and versatility. Designed from high-quality steel alloys, it offers solutions ranging from infrastructure to everyday safety. Its robustness makes steel grating a preferred choice in environments necessitating high reliability, while its adaptability enables use across diverse sectors like construction, manufacturing, and automotive.

The sustainability aspect deserves mention, as steel is recyclable, contributing to environmental conservation efforts. Steel grating can be repurposed, reducing the need for raw material extraction and promoting a circular economy. Engineers and sustainability experts often collaborate to ensure that end-of-life scenarios for these products are as eco-friendly as their use is efficient. Installation of steel grating is straightforward but must adhere to expert protocols to guarantee structural integrity. Depending on the specific application, grating can be anchored using welding or bolted down with specialized clips, ensuring secure placement. Proper installation not only maximizes safety but also optimizes functionality and longevity. The role of steel grating in modern infrastructure is indispensable. Innovations continue to refine these products to better suit current and future demands, whether that's through improved materials, more efficient production methods, or enhanced design specifications. This continuous evolution is driven by industry expertise and the demand for reliable, safe, and sustainable solutions. In summary, steel grating embodies a synthesis of Experience, Expertise, Authoritativeness, and Trustworthiness. Its capabilities are backed by rigorous standards and a long history of effective application across industries. For those seeking materials that deliver on performance and reliability, steel grating remains a prudent choice.

The sustainability aspect deserves mention, as steel is recyclable, contributing to environmental conservation efforts. Steel grating can be repurposed, reducing the need for raw material extraction and promoting a circular economy. Engineers and sustainability experts often collaborate to ensure that end-of-life scenarios for these products are as eco-friendly as their use is efficient. Installation of steel grating is straightforward but must adhere to expert protocols to guarantee structural integrity. Depending on the specific application, grating can be anchored using welding or bolted down with specialized clips, ensuring secure placement. Proper installation not only maximizes safety but also optimizes functionality and longevity. The role of steel grating in modern infrastructure is indispensable. Innovations continue to refine these products to better suit current and future demands, whether that's through improved materials, more efficient production methods, or enhanced design specifications. This continuous evolution is driven by industry expertise and the demand for reliable, safe, and sustainable solutions. In summary, steel grating embodies a synthesis of Experience, Expertise, Authoritativeness, and Trustworthiness. Its capabilities are backed by rigorous standards and a long history of effective application across industries. For those seeking materials that deliver on performance and reliability, steel grating remains a prudent choice.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP