The Advantages of 1% 204% Perforated Steel Plate A Comprehensive Overview

In the realm of modern construction and design, materials play a crucial role in determining the efficacy and aesthetic appeal of an outcome. Among these materials, the 1% 204% perforated steel plate stands out due to its unique traits and versatility. This article delves into the benefits and applications of perforated steel plates, specifically focusing on the 1% 204% variant and why it is gaining traction in various industries.

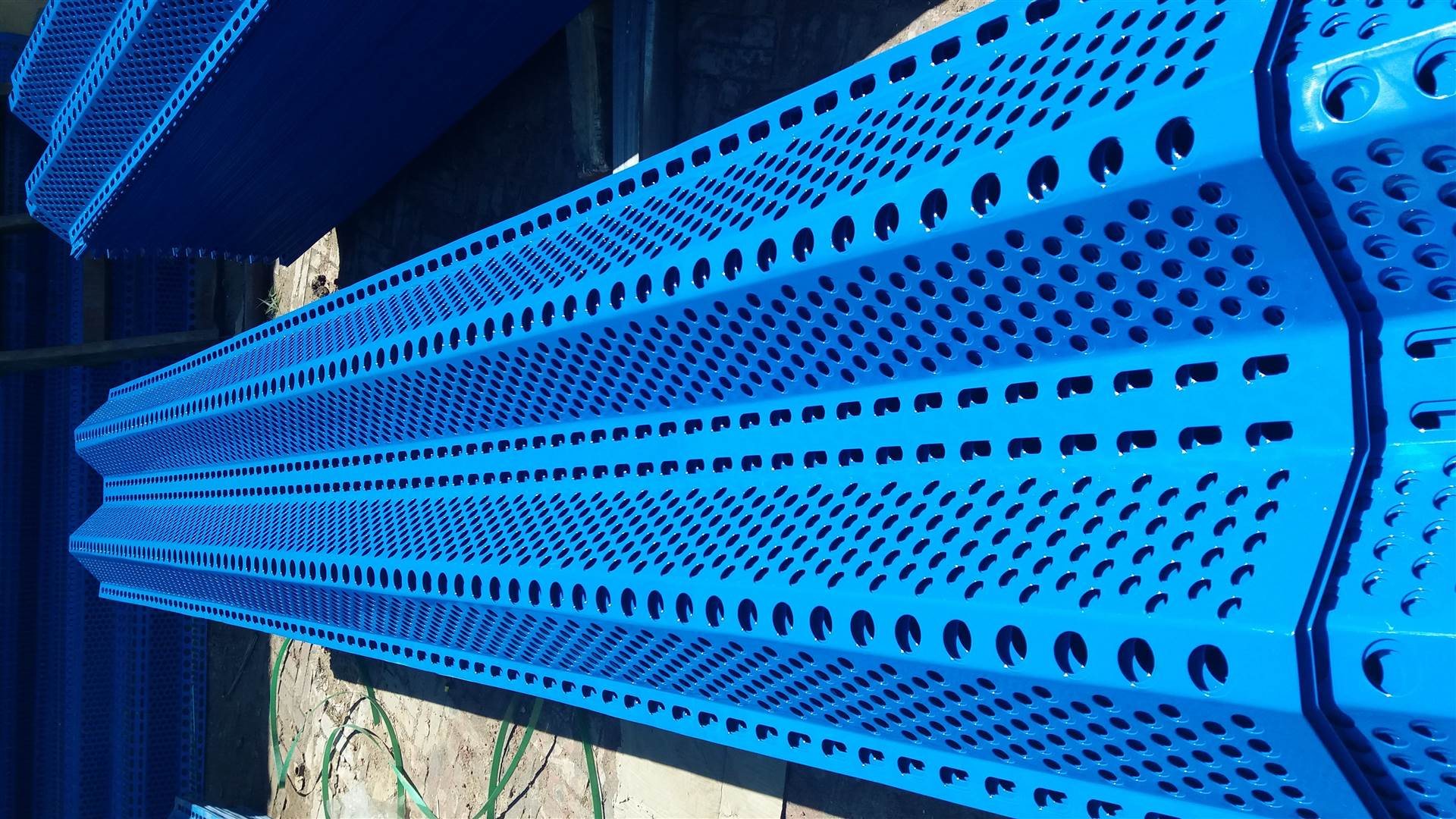

First and foremost, let’s understand what perforated steel plate is. This type of steel plate is characterized by a series of holes or apertures created through a controlled process of punching, laser cutting, or drilling. These perforations can vary in size, shape, and arrangement, lending the material its distinguishable appearance. The term “1% 204%” likely refers to the thickness, percentage of open area, or specific features of the plate that contribute to its lightweight yet resilient nature.

The Advantages of 1% 204% Perforated Steel Plate A Comprehensive Overview

Another noteworthy benefit is its aesthetic flexibility. Perforated steel plates can be manufactured to provide various visual effects, ranging from minimalist designs to intricate patterns. This allows architects and designers to create striking façades that offer both artistic appeal and functional benefits, such as light diffusion and ventilation. In this regard, the 1% 204% perforated steel plate can serve as a statement piece in modern architecture, enhancing the overall design while contributing to energy efficiency.

1 4 perforated steel plate

Furthermore, the open holes in the perforated plate facilitate ventilation and drainage. This is particularly advantageous in applications such as industrial facilities or outdoor spaces where airflow is essential. Utilizing 1% 204% perforated steel can help manage temperature and moisture, thereby preventing issues like rust or degradation in environments prone to extreme conditions.

In terms of sustainability, perforated steel plates are an attractive option because they are often made from recyclable materials. The ability to recycle not only reduces waste but also promotes a circular economy. The 1% 204% variant can be fabricated with minimal environmental impact and can be reused or repurposed once its primary function has been fulfilled.

Lastly, the durability of perforated steel plate cannot be overlooked. Steel is a robust material, and when appropriately treated and coated, it can withstand harsh weather conditions, making it suitable for both indoor and outdoor applications. This longevity translates to lower maintenance costs and less frequent replacement, adding to the overall cost-effectiveness of projects employing this material.

In conclusion, the use of 1% 204% perforated steel plate is increasingly becoming a favored option across various industries due to its unique combination of strength, weight reduction, aesthetic versatility, ventilation properties, sustainability, and durability. Whether in architectural design, industrial applications, or infrastructure projects, this specialized material offers innovative solutions that meet the demands of modern construction while contributing to a sustainable future. As technology advances and design needs evolve, the perforated steel plate will continue to play a pivotal role in shaping the spaces we inhabit.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.