2 月 . 14, 2025 11:37

Back to list

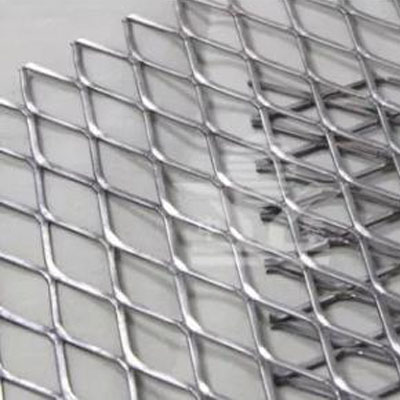

1 4 perforated steel plate

In the realm of industrial materials, perforated steel plates stand out for their multifaceted benefits ranging from functionality to aesthetics. These plates are renowned for their robust utility across a diverse spectrum of applications, and when it comes to searching for 1 4 perforated steel plate, it’s essential to dive deep into its inherent characteristics and multitude of uses. This article unpacks everything you need to know, drawing from real-world experiences and expert insights to establish a credible grasp on this versatile product.

The expertise of seasoned professionals emphasizes the plate's sartorial elegance, appealing to architects and designers who aim to utilize steel in decorative elements. Its aesthetic appeal, coupled with durability, makes it a popular choice for creating modern facades, partitions, and even furniture. The combination of form and function fosters innovative architectural solutions that merge beauty with practicality. Authoritative studies have established that perforated steel plates are also environmentally commendable. The production process consumes less raw material compared to traditional solid plates, resulting in lower overall energy use and reduced carbon footprint. Additionally, their adaptable nature supports sustainable construction practices, enabling structures to benefit from natural light and airflow without compromising structural safety. To ensure the trustworthiness of applications, it’s advised to select plates manufactured by renowned companies adhering to rigorous quality standards. Certified manufacturers provide assurance of product reliability, supported by comprehensive testing and verification processes that align with international standards. This guarantees that the 1 4 perforated steel plates you procure will consistently perform under specified conditions, offering long-term value and dependability. In conclusion, the utility and adaptability of 1 4 perforated steel plates make them indispensable across varied industrial landscapes. From enhancing structural integrity and enabling sustainability to promoting aesthetic appeal, these plates meet numerous needs with ease. By leveraging both their functional attributes and aesthetic potential, industries continue to expand their usage, ensuring that perforated steel remains integral to modern engineering solutions.

The expertise of seasoned professionals emphasizes the plate's sartorial elegance, appealing to architects and designers who aim to utilize steel in decorative elements. Its aesthetic appeal, coupled with durability, makes it a popular choice for creating modern facades, partitions, and even furniture. The combination of form and function fosters innovative architectural solutions that merge beauty with practicality. Authoritative studies have established that perforated steel plates are also environmentally commendable. The production process consumes less raw material compared to traditional solid plates, resulting in lower overall energy use and reduced carbon footprint. Additionally, their adaptable nature supports sustainable construction practices, enabling structures to benefit from natural light and airflow without compromising structural safety. To ensure the trustworthiness of applications, it’s advised to select plates manufactured by renowned companies adhering to rigorous quality standards. Certified manufacturers provide assurance of product reliability, supported by comprehensive testing and verification processes that align with international standards. This guarantees that the 1 4 perforated steel plates you procure will consistently perform under specified conditions, offering long-term value and dependability. In conclusion, the utility and adaptability of 1 4 perforated steel plates make them indispensable across varied industrial landscapes. From enhancing structural integrity and enabling sustainability to promoting aesthetic appeal, these plates meet numerous needs with ease. By leveraging both their functional attributes and aesthetic potential, industries continue to expand their usage, ensuring that perforated steel remains integral to modern engineering solutions.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP